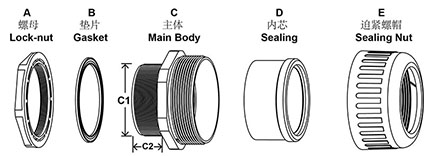

Nylon corrugated pipe joint is a kind of accessory connecting nylon corrugated pipe, which is mainly made of nylon material. Its design adopts high-quality materials and excellent production technology, and has excellent characteristics such as wear resistance, aging resistance, high and low temperature resistance. When used with nylon corrugated pipe, it can greatly increase its durability and service life.

The materials used in this product are high-quality nylon processed through multiple processes. After the durability test, it can be confirmed that it has excellent characteristics such as high wear resistance, high aging resistance, high and low temperature resistance, is not easy to deform and warp, and can ensure that it is still in good condition under low temperature in winter and high temperature in summer.

The design and manufacturing process of this product are produced according to high-end industrial standards, with high pressure bearing capacity and perfect sealing. It is more stable and reliable in use, and is not prone to water leakage, cracking, and other phenomena, making users more confident and safe during the operation process.

The nylon wave pipe joint is simple and easy to use, can be quickly installed without the use of any special tools, and is easy to disassemble, suitable for connecting multiple types of water pipes. The product has a beautiful appearance and adopts a compact structural design, which occupies little space and does not occupy the space of the nylon wave tube connection part, making it easy to install.

The service life of the nylon wave tube joint can be as long as several years. Once installed on the nylon wave tube, it can maintain stable and good operation for a long time. Moreover, due to its strong waterproof, acid and alkali resistance, and weather resistance, the service life is even longer, making it unnecessary for users to replace it frequently and saving maintenance costs.

In a word, nylon corrugated pipe joint is a high-quality water pipe connection fitting, which has excellent wear resistance, aging resistance, high and low temperature resistance, convenient installation and long service life. It is an excellent choice among nylon corrugated pipe fittings, especially suitable for water conservancy, urban construction, chemical, petroleum, fertilizer and other industries.

| Waterproof Corrugated Tubing Fittings | ||||||

| Metric | ||||||

| Thread | Part No. | Matching Pipe | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| M12*1.5 | M12-AD10 | AD10.0 | 1/4" | 12 | 9 | 50 |

| M16*1.5 | M16-AD13.0-ST | AD13.0 | 5/16" | 16 | 10 | 50 |

| M16-AD13.0 | AD13.0 | 5/16" | 16 | 15 | 50 | |

| M16-AD15.8-ST | AD15.8 | 3/8" | 16 | 10 | 50 | |

| M16-AD15.8 | AD15.8 | 3/8" | 16 | 15 | 50 | |

| M16-AD18.5-ST | AD18.5 | 3/8" | 16 | 10 | 50 | |

| M16-AD18.5 | AD18.5 | 3/8" | 16 | 15 | 50 | |

| M20*1.5 | M20-AD15.8-ST | AD15.8 | 3/8" | 20 | 10 | 50 |

| M20-AD15.8 | AD15.8 | 3/8" | 20 | 15 | 50 | |

| M20-AD18.5-ST | AD18.5 | 3/8" | 20 | 10 | 50 | |

| M20-AD18.5 | AD18.5 | 3/8" | 20 | 15 | 50 | |

| M20-AD21.2-ST | AD21.2 | 1/2" | 20 | 10 | 50 | |

| M20-AD21.2 | AD21.2 | 1/2" | 20 | 15 | 50 | |

| M25*1.5 | M25-AD21.2-ST | AD21.2 | 1/2" | 25 | 12 | 50 |

| M25-AD21.2 | AD21.2 | 1/2" | 25 | 15 | 50 | |

| M25-AD25-ST | AD25.0 | 3/4" | 25 | 12 | 50 | |

| M25-AD25.0 | AD25.0 | 3/4" | 25 | 15 | 50 | |

| M25-AD28.5-ST | AD28.5 | 3/4" | 25 | 12 | 50 | |

| M25-AD28.5 | AD28.5 | 3/4" | 25 | 15 | 50 | |

| M32*1.5 | M32-AD34.5-ST | AD34.5 | 1" | 32 | 12 | 20 |

| M32-AD34.5 | AD34.5 | 1" | 32 | 15 | 20 | |

| M40*1.5 | M40-AD42.5 | AD42.5 | 1 1/4" | 40 | 15 | 10 |

| M50*1.5 | M50-AD42.5 | AD42.5 | 1 1/4" | 50 | 22 | 10 |

| M50-AD54.5 | AD54.5 | 2" | 50 | 22 | 10 | |

| M63*1.5 | M63-AD54.5 | AD54.5 | 2" | 63 | 25 | 10 |

| PG | ||||||

| Thread | Part No. | Matching Pipe | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| PG7 | PG7-AD10.0 | AD10.0 | 1/4" | 12.5 | 9 | 50 |

| PG9 | PG9-AD10.0 | AD10.0 | 1/4" | 15.2 | 9 | 50 |

| PG11 | PG11-AD13.0 | AD13.0 | 5/16" | 18.6 | 10 | 50 |

| PG13.5 | PG13.5-AD15.8 | AD15.8 | 3/8" | 20.4 | 10 | 50 |

| PG13.5-AD18.5 | AD18.5 | 3/8" | 20.4 | 10 | 50 | |

| PG16 | PG16-AD15.8 | AD15.8 | 3/8" | 22.5 | 11 | 50 |

| PG16-AD18.5 | AD18.5 | 3/8" | 22.5 | 11 | 50 | |

| PG16-AD21.2 | AD21.2 | 1/2" | 22.5 | 11 | 50 | |

| PG21 | PG21-AD21.2 | AD21.2 | 1/2" | 28.3 | 12 | 50 |

| PG21-AD25.0 | AD25.0 | 3/4" | 28.3 | 12 | 50 | |

| PG21-AD28.5 | AD28.5 | 3/4" | 28.3 | 12 | 50 | |

| PG29 | PG29-AD34.5 | AD34.5 | 1" | 37 | 13 | 20 |

| PG36 | PG36-AD42.5 | AD42.5 | 1 1/4" | 47 | 13 | 10 |

| PG42 | PG42-AD42.5 | AD42.5 | 1 1/4" | 54 | 16 | 10 |

| PG48 | PG48-AD54.5 | AD54.5 | 2" | 59.3 | 16 | 10 |

| G | ||||||

| Thread | Part No. | Matching Pipe | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| G(PF)1/4" | PF1/4-AD10.0 | AD10.0 | 1/4" | 13.1 | 9 | 50 |

| G(PF)3/8" | PF3/8-AD13.0 | AD13.0 | 5/16" | 16.6 | 15 | 50 |

| G(PF)1/2" | PF1/2-AD15.8 | AD15.8 | 3/8" | 20.9 | 15 | 50 |

| PF1/2-AD18.5 | AD18.5 | 3/8" | 20.9 | 15 | 50 | |

| PF1/2-AD21.2 | AD21.2 | 1/2" | 20.9 | 15 | 50 | |

| PF1/2-AD25 | AD25.0 | 3/4" | 20.9 | 15 | 50 | |

| G(PF)3/4" | PF3/4-AD21.2 | AD21.2 | 1/2" | 26.4 | 15 | 50 |

| PF3/4-AD25.0 | AD25.0 | 3/4" | 26.4 | 15 | 50 | |

| PF3/4-AD28.5 | AD28.5 | 3/4" | 26.4 | 15 | 50 | |

| G(PF)1" | PF1-AD34.5 | AD34.5 | 1" | 33.2 | 15 | 20 |

| G(PF)1 1/4" | PF1 1/4-AD42.5 | AD42.5 | 1 1/4" | 41.9 | 15 | 10 |

| G(PF)1 1/2" | PF1 1/2-AD54.5 | AD54.5 | 2" | 48 | 15 | 10 |

| G(PF)2" | PF2-AD54.5 | AD54.5 | 2" | 60 | 15 | 10 |

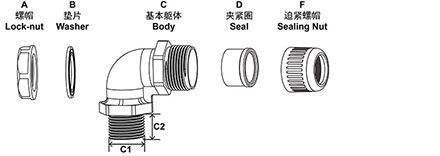

Nylon corrugated pipe joint is a kind of accessory connecting nylon corrugated pipe, which is mainly made of nylon material. Its design adopts high-quality materials and excellent production technology, and has excellent characteristics such as wear resistance, aging resistance, high and low temperature resistance. When used with nylon corrugated pipe, it can greatly increase its durability and service life.

The materials used in this product are high-quality nylon processed through multiple processes. After the durability test, it can be confirmed that it has excellent characteristics such as high wear resistance, high aging resistance, high and low temperature resistance, is not easy to deform and warp, and can ensure that it is still in good condition under low temperature in winter and high temperature in summer.

The design and manufacturing process of this product are produced according to high-end industrial standards, with high pressure bearing capacity and perfect sealing. It is more stable and reliable in use, and is not prone to water leakage, cracking, and other phenomena, making users more confident and safe during the operation process.

The nylon wave pipe joint is simple and easy to use, can be quickly installed without the use of any special tools, and is easy to disassemble, suitable for connecting multiple types of water pipes. The product has a beautiful appearance and adopts a compact structural design, which occupies little space and does not occupy the space of the nylon wave tube connection part, making it easy to install.

The service life of the nylon wave tube joint can be as long as several years. Once installed on the nylon wave tube, it can maintain stable and good operation for a long time. Moreover, due to its strong waterproof, acid and alkali resistance, and weather resistance, the service life is even longer, making it unnecessary for users to replace it frequently and saving maintenance costs.

In a word, nylon corrugated pipe joint is a high-quality water pipe connection fitting, which has excellent wear resistance, aging resistance, high and low temperature resistance, convenient installation and long service life. It is an excellent choice among nylon corrugated pipe fittings, especially suitable for water conservancy, urban construction, chemical, petroleum, fertilizer and other industries.

| Elbow Waterproof Corrugated Tubing Fittings | ||||||

| Metric | ||||||

| Thread | Part No. | Matching Pipe | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| M12*1.5 | MW12-E-AD10.0 | AD10.0 | 1/4" | 12 | 12 | 50 |

| M16*1.5 | MW16-E-AD13.0 | AD13.0 | 5/16" | 16 | 15 | 50 |

| MW16-E-AD15.8 | AD15.8 | 3/8" | 16 | 15 | 50 | |

| MW16-E-AD18.5 | AD18.5 | 3/8" | 16 | 15 | 50 | |

| M20*1.5 | MW20-E-AD15.8 | AD15.8 | 3/8" | 20 | 15 | 50 |

| MW20-E-AD18.5 | AD18.5 | 3/8" | 20 | 15 | 50 | |

| MW20-E-AD21.2 | AD21.2 | 1/2" | 20 | 15 | 50 | |

| M25*1.5 | MW25-E-AD21.2 | AD21.2 | 1/2" | 25 | 15 | 50 |

| MW25-E-AD25.0 | AD25.0 | 3/4" | 25 | 15 | 50 | |

| MW25-E-AD28.5 | AD28.5 | 3/4" | 25 | 15 | 50 | |

| M32*1.5 | MW32-E-AD34.5 | AD34.5 | 1" | 32 | 15 | 20 |

| M40*1.5 | MW40-E-AD42.5 | AD42.5 | 1 1/4" | 40 | 15 | 10 |

| M50*1.5 | MW50-E-AD54.5 | AD54.5 | 2" | 50 | 22 | 10 |

| M63*1.5 | MW63-E-AD54.5 | AD54.5 | 2" | 63 | 25 | 10 |

| PG | ||||||

| Thread | Part No. | Matching Pipe | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| PG16 | PGW16-E-AD15.8 | AD15.8 | 3/8" | 22.5 | 11 | 50 |

| PGW16-E-AD18.5 | AD18.5 | 3/8" | 22.5 | 11 | 50 | |

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

1.First confirm the hole diameter of flexible corrguated pipe

2.Find the matching thread international standard according to the technical parameter table (Metric,PG,NPT,G) .

Answer: We have finished UL listed and raw material UL approved .You can choose the one you want according to your requirement .

2.Question: How long is the working life of quick connector?

Answer:More than 10 years under normal environment.

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 businessdays.

4.Question: Can be accept OEM quick connector & packing?

Answer: Yes,OEM,ODM can be accepted .

5.Question: If we buy your product and find quality problems, how to solve it?

Answer: If quality problems are caused by us instead of external reasons, we will compensate each item to the customer