Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

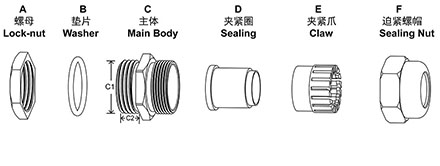

The cable gland is made of high-quality stainless steel, and has undergone strict quality control in the manufacturing process to ensure its reliable quality. This product can effectively resist various harmful elements in the environment, such as water, dust, and chemicals. The cable gland reliably ensures the safety and integrity of the cable connector regardless of weather and terrain conditions.

The stainless steel cable gland has excellent waterproof performance, which can still effectively protect cable connectors in harsh environments such as oceans, coasts, and high altitudes. It can also effectively protect cable connectors from damage in harsh conditions such as rain, snow, and strong winds. Therefore, this product is very suitable for cable connectors used outdoors.

Moreover, the tensile performance of the sealing sleeve is also very strong. It can easily withstand strong pulling force, ensuring that the cable connector is securely and firmly fixed in position, avoiding situations where the cable connection becomes loose or detached due to excessive pulling force.

In addition to its excellent waterproof and tensile properties, the cable gland also exhibits astonishing high-temperature resistance. Even in high-temperature environments, it can still ensure the safe and reliable connection of cables. This product can withstand high temperatures up to 120 ° C. Therefore, this sealing sleeve is very suitable for use in situations that require high-temperature operations, especially in fields such as oil, natural gas extraction, or high-precision machine manufacturing.

Finally, the clamping range of the cable gland is very large, making it easy to handle different specifications and types of cable connectors. Regardless of the shape and size of the cable, it can perfectly fit and tighten, effectively achieving waterproofing and connection effects.

In summary, this metal stainless steel cable gland is a high-quality and highly reliable cable connector protection device, with excellent waterproof, tensile, high-temperature resistance, and a wide clamping range. It is a reliable cable protection device suitable for various work occasions, such as aviation, ships, mines, machine manufacturing, and so on.

| Stainless Steel Cable Gland | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M10*1.0 | M10-6.5 | 3-6.5 | 10 | 6.5 | 14/14 | 50 |

| M12*1.5 | M12-6.5 | 3-6.5 | 12 | 6.5 | 14/14 | 50 |

| M14*1.5 | M14-8 | 4-8 | 14 | 7 | 17/17 | 50 |

| M16*1.5 | M16-8 | 4-8 | 16 | 8 | 18/18 | 50 |

| M18*1.5 | M18-10 | 5-10 | 18 | 8 | 20/20 | 50 |

| M20*1.5 | M20-12 | 6-12 | 20 | 8 | 22/22 | 50 |

| M22*1.5 | M22-14 | 10-14 | 22 | 8 | 24/24 | 50 |

| M24*1.5 | M24-14 | 10-14 | 24 | 9 | 27/24 | 50 |

| M25*1.5 | M25-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| M25-16 | 12-16 | 25 | 9 | 27/27 | 50 | |

| M25-18 | 13-18 | 25 | 9 | 27/30 | 50 | |

| M27*1.5(2) | M27-18 | 13-18 | 27 | 9 | 30/30 | 50 |

| M28*1.5(2) | M28-18 | 13-18 | 28 | 9 | 30/30 | 50 |

| M30*1.5(2) | M30-18 | 13-18 | 30 | 9 | 32/30 | 50 |

| M32*1.5(2) | M32-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| M33*1.5(2) | M33-22 | 15-22 | 33 | 10 | 35/35 | 50 |

| M36*1.5(2) | M36-25 | 18-25 | 36 | 10 | 40/40 | 50 |

| M37*1.5(2) | M37-25 | 18-25 | 37 | 10 | 40/40 | 50 |

| M40*1.5(2) | M40-30 | 22-30 | 40 | 11 | 45/45 | 50 |

| M42*1.5(2) | M42-30 | 22-30 | 42 | 11 | 45/45 | 50 |

| M47*1.5(2) | M47-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| M48*1.5(2) | M48-33 | 25-33 | 48 | 11 | 50/52 | 50 |

| M50*1.5(2) | M50-38 | 32-38 | 50 | 13 | 55/57 | 50 |

| M54*1.5(2) | M54-38 | 32-38 | 54 | 13 | 55/57 | 50 |

| M60*1.5(2) | M60-44 | 37-44 | 60 | 14 | 64/64 | 50 |

| M63*1.5(2) | M63-44 | 37-44 | 63 | 14 | 68/64 | 50 |

| M64*1.5(2) | M64-44 | 37-44 | 64 | 14 | 68/64 | 50 |

| M72*1.5(2) | M72-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| M75*1.5(2) | M75-52 | 42-52 | 75 | 16 | 78/78 | 50 |

| M80*1.5(2) | M80-62 | 55-62 | 80 | 18 | 88/88 | 50 |

| M88*1.5(2) | M88-70 | 65-70 | 88 | 18 | 94/94 | 50 |

| M100*1.5(2) | M100-84 | 78-84 | 100 | 20 | 110/110 | 50 |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PG7-6.5 | 3-6.5 | 12.5 | 6.5 | 14/14 | 50 |

| PG9 | PG9-8 | 4-8 | 15.2 | 7 | 17/17 | 50 |

| PG11 | PG11-10 | 5-10 | 18.6 | 8 | 20/20 | 50 |

| PG13.5 | PG13.5-12 | 6-12 | 20.4 | 8 | 22/22 | 50 |

| PG16 | PG16-14 | 10-14 | 22.5 | 9 | 24/24 | 50 |

| PG19 | PG19-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| PG21 | PG21-18 | 13-18 | 28.3 | 9 | 30/30 | 50 |

| PG25 | PG25-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| PG29 | PG29-25 | 18-25 | 37 | 11 | 40/40 | 50 |

| PG36 | PG36-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| PG42 | PG42-38 | 32-38 | 54 | 13 | 57/57 | 50 |

| PG48 | PG48-44 | 37-44 | 59.3 | 14 | 64/64 | 50 |

| PG63 | PG63-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| G | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G1/4 | G1/4 | 3-6.5 | 13.1 | 6 | 14/14 | 50 |

| G3/8 | G3/8 | 4-8 | 16.6 | 8 | 18/18 | 50 |

| G1/2 | G1/2 | 6-12 | 20.9 | 8 | 22/22 | 50 |

| G3/4 | G3/4 | 13-18 | 26.4 | 9 | 30/30 | 50 |

| G1 | G1 | 18-25 | 33.2 | 10 | 40/40 | 50 |

| G1-1/4 | G1-1/4 | 25-33 | 41.9 | 13 | 50/50 | 50 |

| G1-1/2 | G1-1/2 | 32-38 | 47.8 | 14 | 57/57 | 50 |

| G2 | G2 | 37-44 | 59.6 | 14 | 64/64 | 50 |

| G2-1/2 | G2-1/2 | 42-52 | 75.1 | 15 | 77/77 | 50 |

| G3 | G3 | 65-70 | 87.8 | 15 | 94/94 | 50 |

| NPT | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| NPT1/4 | NPT1/4 | 3-6.5 | 13.6 | 6 | 14/14 | 50 |

| NPT3/8 | NPT3/8 | 4-8 | 17 | 8 | 18/18 | 50 |

| NPT1/2 | NPT1/2 | 6-12 | 21.2 | 8 | 22/22 | 50 |

| NPT3/4 | NPT3/4 | 13-18 | 26.5 | 9 | 30/30 | 50 |

| NPT1 | NPT1 | 18-25 | 33.2 | 11 | 40/40 | 50 |

| NPT1-1/4 | NPT1-1/4 | 25-33 | 41.9 | 13 | 50/50 | 50 |

| NPT1-1/2 | NPT1-1/2 | 32-38 | 48 | 14 | 57/57 | 50 |

| NPT2 | NPT2 | 37-44 | 60 | 14 | 64/64 | 50 |

| NPT2-1/2 | NPT2-1/2 | 42-52 | 72.6 | 15 | 77/77 | 50 |

| NPT3 | NPT3 | 65-70 | 88.6 | 15 | 94/94 | 50 |

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel.

2.Choosing the correct thread international standard.(Metric,PG,NPT,G).

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread .

1.Question: Can customize long thread of metal cable gland ?

Answer: Yes. The shape and screw length of ordinary metal products can be customized after 3D & CAD drawings are provided without new molds (except for special appearance products).

2.Question:Does the signal lamp affect the magnetic field?

Answer:This product can also be used with armor wires to achieve the purpose of EMC anti-magnetic wave.

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.Customized model based on the QTY.