| Nylon Quick Connector | ||||||

| Metric | ||||||

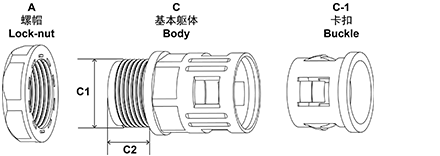

| Thread | Part No. | Matching Pipc | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| M12*1.5 | M12-AD10.0 | AD10.0 | 1/4" | 12 | 10 | 50 |

| M12-AD13.0 | AD13.0 | 5/16" | 12 | 10 | .50 | |

| M16*1.5 | M16-AD13.0 | AD13..0 | 5/16" | 16 | 10 | 50 |

| M16-AD15.8 | AD15.8 | 3/8" | 16 | 10 | 50 | |

| M18*1.5 | M18-AD13.0 | AD13.0 | 5/16" | 18 | 12.5 | 50 |

| M18-AD15.8 | AD15.8 | 3/8" | 18 | 12.5 | 50 | |

| M20*1.5 | M20-AD15.8 | AD15.8 | 3/8" | 20 | 10 | 50 |

| M20-AD18.5 | AD18.5 | 3/8" | 20 | 15 | 50 | |

| M20-AD21.2 | AD21.2 | 1/2" | 20 | 10 | 50 | |

| M22*1.5 | M22-AD18.5 | AD18.5 | 3/8" | 22 | 10 | 50 |

| M24*1.5 | M24-AD21.2 | AD21.2 | 1/2" | 24 | 13 | 50 |

| M25*1.5 | M25-AD21.2 | AD21.2 | 1/2" | 25 | 13 | 50 |

| M25-AD25 | AD25 | 3/4" | 25 | 13 | 50 | |

| M25-AD28.5 | AD28.5 | 3/4" | 25 | 13 | 50 | |

| M27*1.5 | M27-AD28.5 | AD28.5 | 3/4" | 27 | 13 | 50 |

| M32*1.5 | M32-AD28.5 | AD28.5 | 3/4" | 32 | 13 | 50 |

| M32-AD34.5 | AD34.5 | 1" | 32 | 14 | 50 | |

| M36*1.5 | M36-AD34.5 | AD34.5 | 1" | 36 | 14 | 50 |

| M40*1.5 | M40-AD34.5 | AD34.5 | 1" | 40 | 15 | 20 |

| M40-AD42.5 | AD42.5 | 1 1/4" | 40 | 15 | 12 | |

| M48*1.5 | M48-AD42.5 | AD42.5 | 1 1/4" | 48 | 15 | 10 |

| M50*1.5 | M50-AD54.5 | AD54.5 | 2" | 50 | 16 | 10 |

| M63*1.5 | M63-AD54.5 | AD54.5 | 2" | 63 | 16 | 10 |

| PG | ||||||

| Thread | Part No. | Matching Pipc | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| PG7 | PG7-AD10.0 | AD10.0 | 1/4" | 12.5 | 8.5 | 50 |

| PG9 | PG9-AD13.0 | AD13.0 | 5/16" | 15.2 | 10 | 50 |

| PG11 | PG11-AD15.8 | AD15.8 | 3/8" | 18.6 | 12.5 | 50 |

| PG13.5 | PG13.5-AD15.8 | AD15.8 | 3/8" | 20.4 | 12.5 | 50 |

| PG13.5-AD18.5 | AD18.5 | 3/8" | 20.4 | 12.5 | 50 | |

| PG16 | PG16-AD21.2 | AD21.2 | 1/2" | 22.5 | 13 | 50 |

| PG21 | PG21-AD25.0 | AD25.0 | 3/4" | 28.3 | 13 | 50 |

| PG21-AD28.5 | AD28.5 | 3/4" | 28.3 | 13 | 20 | |

| PG29 | PG29-AD34.5 | AD34.5 | 1" | 37 | 14 | 10 |

| PG36 | PG36-AD42.5 | AD42.5 | 1 1/4" | 47 | 15 | 10 |

| PG42 | PG42-AD42.5 | AD42.5 | 1 1/4" | 54 | 16 | 10 |

| PG48 | PG48-AD54.5 | AD54.5 | 2" | 59.3 | 16 | 10 |

| G | ||||||

| Thread | Part No. | Matching Pipc | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| G(PF)1/4" | G(PF)1/4"-AD10.0 | AD10.0 | 1/4" | 13.1 | 8.5 | 50 |

| G(PF)3/8" | G(PF)3/8"-AD13.0 | AD13.0 | 5/16" | 16.6 | 10 | 50 |

| G(PF)3/8"-AD15.8 | AD15.8 | 3/8" | 16.6 | 12.5 | 50 | |

| G(PF)1/2" | G(PF)1/2"-AD15.8 | AD15.8 | 3/8" | 20.9 | 12.5 | 50 |

| G(PF)1/2"-AD18.5 | AD18.5 | 3/8" | 20.9 | 12.5 | 50 | |

| G(PF)1/2"-AD21.2 | AD21.2 | 1/2" | 20.9 | 13 | 50 | |

| G(PF)3/4" | G(PF)3/4"-AD21.2 | AD21.2 | 1/2" | 26.4 | 13 | 50 |

| G(PF)3/4"-AD25.0 | AD25.0 | 3/4" | 26.4 | 13 | 50 | |

| G(PF)3/4"-AD28.5 | AD28.5 | 3/4" | 26.4 | 13 | 50 | |

| G(PF)1" | G(PF)1"-AD34.5 | AD34.5 | 1" | 33.2 | 14 | 20 |

| G(PF)1 1/4" | G(PF)1 1/4"-AD42.5 | AD42.5 | 1 1/4" | 41.9 | 15 | 10 |

| G(PF)1 1/2" | G(PF)1 1/2"-AD42.5 | AD42.5 | 1 1/4" | 48 | 16 | 10 |

| G(PF)2" | G(PF)2"-AD54.5 | AD54.5 | 2" | 60 | 16 | 10 |

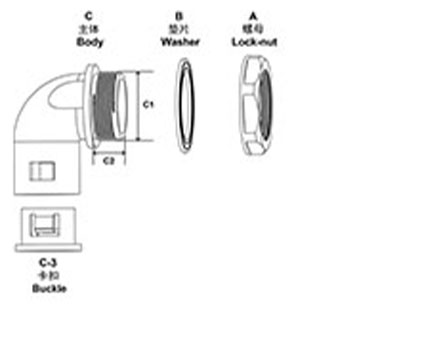

| 90°Nylon Quick Connector | ||||||

| Metric | ||||||

| Thread | Part No. | Matching Pipc | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| M12*1.5 | M12-AD10.0 | AD10.0 | 1/4" | 12 | 10 | 50 |

| M12-AD13.0 | AD13.0 | 5/16" | 12 | 10 | 50 | |

| M16*1.5 | M16-AD13.0 | AD13.0 | 5/16" | 16 | 10 | 50 |

| M16-AD15.8 | AD15.8 | 3/8" | 16 | 10 | 50 | |

| M18*1.5 | M18-AD13.0 | AD13 | 5/16" | 18 | 12.5 | 50 |

| M18-AD15.8 | AD15.8 | 3/8" | 18 | 12.5 | 50 | |

| M20*1.5 | M20-AD15.8 | AD15.8 | 3/8" | 20 | 10 | 50 |

| M20-AD18.5 | AD18.5 | 3/8" | 20 | 15 | 50 | |

| M20-AD21.2 | AD21.2 | 1/2" | 20 | 10 | 50 | |

| M22*1.5 | M22-AD18.5 | AD18.5 | 3/8" | 22 | 10 | 50 |

| M24*1.5 | M24-AD21.2 | AD21.2 | 1/2" | 24 | 13 | 50 |

| M25*1.5 | M25-AD21.2 | AD21.2 | 1/2" | 25 | 13 | 50 |

| M25-AD25.0 | AD25.0 | 3/4" | 25 | 13 | 50 | |

| M25-AD28.5 | AD28.5 | 3/4" | 25 | 13 | 50 | |

| M27*1.5 | M27-AD28.5 | AD28.5 | 3/4" | 27 | 13 | 50 |

| M32*1.5 | M32-AD28.5 | AD28.5 | 3/4" | 32 | 13 | 50 |

| M32-AD34.5 | AD34.5 | 1" | 32 | 14 | 50 | |

| M36*1.5 | M36-AD34.5 | AD34.5 | 1" | 36 | 14 | 50 |

| M40*1.5 | M40-AD34.5 | AD34.5 | 1" | 40 | 15 | 20 |

| M40-AD42.5 | AD42.5 | 1 1/4" | 40 | 15 | 12 | |

| M48*1.5 | M48-AD42.5 | AD42.5 | 1 1/4" | 48 | 15 | 10 |

| M50*1.5 | M50-AD54.5 | AD54.5 | 2" | 50 | 16 | 10 |

| M63*1.5 | M63-AD54.5 | AD54.5 | 2" | 63 | 16 | 10 |

| PG | ||||||

| Thread | Part No. | Matching Pipc | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| PG7 | PG7-AD10.0 | AD10.0 | 1/4" | 12.5 | 8.5 | 50 |

| PG9 | PG9-AD13.0 | AD13.0 | 5/16" | 15.2 | 10 | 50 |

| PG11 | PG11-AD15.8 | AD15.8 | 3/8" | 18.6 | 12.5 | 50 |

| PG13.5-AD18.5 | AD18.5 | 3/8" | 20.4 | 12.5 | 50 | |

| PG16 | PG16-AD21.2 | AD21.2 | 1/2" | 22.5 | 13 | 50 |

| PG21 | PG21-AD25.0 | AD25.0 | 3/4" | 28.3 | 13 | 50 |

| PG21-AD28.5 | AD28.5 | 3/4" | 28.3 | 13 | 50 | |

| PG29 | PG29-AD34.5 | AD34.5 | 1" | 37 | 14 | 20 |

| PG36 | PG36-AD42.5 | AD42.5 | 1 1/4" | 47 | 15 | 10 |

| PG42 | PG42-AD42.5 | AD42.5 | 1 1/4" | 54 | 16 | 10 |

| PG48 | PG48-AD54.5 | AD54.5 | 2" | 59.3 | 16 | 10 |

| G | ||||||

| Thread | Part No. | Matching Pipc | Thread O.D C1(mm) |

Thread Length C2(mm) |

Std.pkg (pcs/bag) |

|

| G(PF)1/4" | G(PF)1/4"-AD10.0 | AD10.0 | 1/4" | 13.1 | 8.5 | 50 |

| G(PF)3/8" | G(PF)3/8"-AD13.0 | AD13.0 | 5/16" | 16.6 | 10 | 50 |

| G(PF)3/8"-AD15.8 | AD15.8 | 3/8" | 16.6 | 12.5 | 50 | |

| G(PF)1/2" | G(PF)1/2"-AD15.8 | AD15.8 | 3/8" | 20.9 | 12.5 | 50 |

| G(PF)1/2"-AD18.5 | AD18.5 | 3/8" | 20.9 | 12.5 | 50 | |

| G(PF)1/2"-AD21.2 | AD21.2 | 1/2" | 20.9 | 13 | 50 | |

| G(PF)3/4" | G(PF)3/4"-AD21.2 | AD21.2 | 1/2" | 26.4 | 13 | 50 |

| G(PF)3/4"-AD25 | AD25 | 3/4" | 26.4 | 13 | 50 | |

| G(PF)3/4"-AD28.5 | AD28.5 | 3/4" | 26.4 | 13 | 50 | |

| G(PF)1" | G(PF)1"-AD34.5 | AD34.5 | 1" | 33.2 | 14 | 20 |

| G(PF)1 1/4" | G(PF)1 1/4"-AD42.5 | AD42.5 | 1 1/4" | 41.9 | 15 | 12 |

| G(PF)1 1/2" | G(PF)1 1/2"-AD42.5 | AD42.5 | 1 1/4" | 48 | 16 | 10 |

| G(PF)2" | G(PF)2"-AD54.5 | AD54.5 | 2" | 60 | 16 | 10 |

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

1.First confirm the hole diameter of flexible corrguated pipe

2.Find the matching thread international standard according to the technical parameter table (Metric,PG,NPT,G) .

1.Question: Are they UL listed?

Answer: We have finished UL listed and raw material UL approved .You can choose the one you want according to your requirement .

2.Question: How long is the working life of quick connector?

Answer:More than 10 years under normal environment.

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 businessday