Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

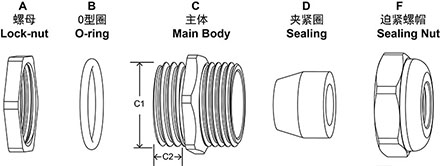

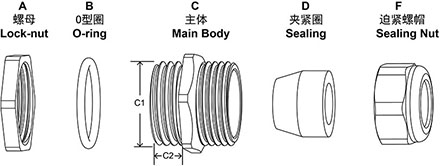

| Metric | ||||||

| Thread | Code | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M8*0.5 | 1 | 5-5.5 | 8 | 4 | 12/11 | 50 |

| M8*0.5 | 2 | 3-4.5 | 8 | 4 | 12/11 | 50 |

| M10*1.5 | 3 | 4-5.5 | 10 | 6 | 14/14 | 50 |

| M10*1.5 | 4 | 4-6.2 | 10 | 6 | 14/14 | 50 |

| M12*1.5 | 5 | 5-6.5 | 12 | 4 | 14/16 | 50 |

| M12*1.5 | 6 | 4.5-7.8 | 12 | 5.5 | 14/15 | 50 |

| M12*1.5 | 7 | 5-6.5 | 12 | 6 | 15/15 | 50 |

| M12*1.5 | 8 | 4.5-6.5 | 12 | 6 | 14/16 | 50 |

| M12*1.5 | 9 | 6.5-8 | 12 | 8 | 14/16 | 50 |

| M12*1.5 | 10 | 6.5-8 | 12 | 8 | 14/16 | 50 |

| M16*1.5 | 11 | 6.5-8 | 16 | 9 | 18/18 | 50 |

| M16*1.5 | 12 | 6.5-8 | 16 | 9 | 18/18 | 50 |

| M16*1.5 | 13 | 8-10 | 16 | 9 | 18/20 | 50 |

Installation requirements

1. When peeling and cutting cables, it should be completed all at once to minimize the time of insulation exposure. The insulation layer should be retained and the wire core should not be damaged.

2. If there is a potential difference between the two ends of the cable line, the joints at the lower position should be constructed first.

3. When connecting cable terminals and connectors, sealing, moisture-proof and mechanical protection measures should be taken, and attention should be paid to strengthening insulation.

4. When connecting a three core oil-paper insulated cable, a 25mm insulation material should be left behind. After removing the shielding carbon ink paper, it should be ensured that the end is flat. When applying force to the curve core, it should be as uniform as possible to avoid damaging the wire core.

5. The metal shielding layer and armor layer of the cables on both sides of the joint should be well connected without interruption. If the cable needs to be buried directly, the metal protective layer should be well protected against corrosion.

6. When connecting, the oil stains inside the wire core and connector should be removed. After crimping, the protrusions at the connection should be smoothed to avoid burrs.

7. Cable accessories, such as grounding boxes, cross interconnection boxes, cross interconnection boxes, etc., should be designed in accordance with the specifications.

8. When installing joints, sealing measures such as sealing, moisture-proof, and sealing measures should be taken at the connection points.

"Protect wires from chafing against drilled holes. Using weather resistant silicone material for seal part ,which acts as a guard from the sharp sheet metal edges. Effectively solves the technical problems existing in the existing technology related to the use of power equipment, such as the cable joint is easy to aging and blistering after long-term use, making its elasticity disappear, or even separated from each other. It ensures the insulation, shielding and sealing performance of cable joints after long-term use.

It is mainly used for lifting and conveying of raw water and sewage, water supply and cooling circulating water of thermal power plant, pipeline conveying of chemical substances in metallurgical industry, condensate water, chemical industry, cooling and dilution in petrochemical industry and flexible connection between long and short distance pipelines in other industries. Because rubber has high wear resistance, it is also suitable for all industries of granular and powdery and low-temperature transportation of vapor."

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel.

2.Choosing the correct thread international standard.(Metric,PG,NPT,G).

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread .

4.Long thread type of cable gland is required by the thickness of mounting panel .