Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

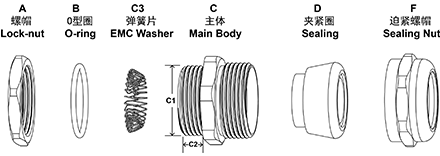

| Spring EMC Metal Cable Gland | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M12*1.5 | M12-6.5 | 3-6.5 | 12 | 6 | 14/14 | 50 |

| M16*1.5 | M16-8 | 4-8 | 16 | 6 | 20/20 | 50 |

| M20*1.5 | M20-12 | 6-12 | 20 | 6 | 24/24 | 50 |

| M25*1.5 | M25-14 | 10-14 | 25 | 7 | 27/24 | 50 |

| M25-16 | 12-16 | 25 | 7 | 27/27 | 50 | |

| M25-18 | 13-18 | 25 | 7 | 27/30 | 50 | |

| M32*1.5(2) | M32-22 | 15-22 | 32 | 8 | 40/40 | 50 |

| M40*1.5(2) | M40-30 | 22-30 | 40 | 8 | 50/50 | 50 |

| M50*1.5(2) | M50-38 | 32-38 | 50 | 9 | 55/57 | 50 |

| M63*1.5(2) | M63-44 | 37-44 | 63 | 10 | 68/64 | 50 |

| M75*1.5(2) | M75-56 | 48-56 | 75 | 15 | 81/81 | 50 |

| M85*1.5(2) | M85-70 | 62-70 | 85 | 15 | 95/95 | 50 |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PG7-6.5 | 3-6.5 | 12.5 | 6 | 14/14 | 50 |

| PG9 | PG9-8 | 4-8 | 15.2 | 6 | 20/20 | 50 |

| PG11 | PG11-10 | 5-10 | 18.6 | 6 | 20/20 | 50 |

| PG13.5 | PG13.5-12 | 6-12 | 20.4 | 6.5 | 24/24 | 50 |

| PG16 | PG16-14 | 10-14 | 22.5 | 6.5 | 24/24 | 50 |

| PG21 | PG21-18 | 13-18 | 28.3 | 7 | 30/30 | 50 |

| PG29 | PG29-25 | 18-25 | 37 | 8 | 40/40 | 50 |

| PG36 | PG36-33 | 25-32 | 47 | 8 | 50/50 | 50 |

| PG42 | PG42-38 | 32-38 | 54 | 9 | 57/57 | 50 |

| PG48 | PG48-44 | 37-44 | 59.3 | 10 | 68/68 | 50 |

| G | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G1/4 | G1/4 | 3-6.5 | 13.1 | 8 | 17/17 | 50 |

| G3/8 | G3/8 | 5-10 | 16.6 | 9 | 20/20 | 50 |

| G1/2 | G1/2 | 10-14 | 20.9 | 9 | 24/24 | 50 |

| G3/4 | G3/4 | 13-18 | 26.4 | 12 | 30/30 | 50 |

| G1 | G1 | 18-25 | 33.2 | 12 | 40/40 | 50 |

| G1-1/4 | G1-1/4 | 25-32 | 41.9 | 15 | 50/50 | 50 |

| G1-1/2 | G1-1/2 | 32-38 | 47.8 | 15 | 57/57 | 50 |

| G2 | G2 | 37-44 | 59.6 | 15 | 64/64 | 50 |

| NPT | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| NPT1/4 | NPT1/4 | 3-6.5 | 13.6 | 13 | 17/17 | 50 |

| NPT3/8 | NPT3/8 | 5-10 | 17 | 13 | 20/20 | 50 |

| NPT1/2 | NPT1/2 | 10-14 | 21.2 | 13 | 24/24 | 50 |

| NPT3/4 | NPT3/4 | 13-18 | 26.5 | 13 | 30/30 | 50 |

| NPT1 | NPT1 | 18-25 | 33.2 | 15 | 40/40 | 50 |

| NPT1-1/4 | NPT1-1/4 | 25-33 | 41.9 | 17 | 54/54 | 50 |

| NPT1-1/2 | NPT1-1/2 | 32-38 | 48 | 15 | 50/50 | 50 |

| NPT2 | NPT2 | 37-44 | 60 | 20 | 64/64 | 50 |

Metal EMC cable glands are an important device used to protect cables and machines from electromagnetic interference. Its installation is very important, not only related to the service life of the equipment, but also to the safety of personnel. Therefore, when installing metal EMC cable glands, the following points need to be noted:

1. Choose the appropriate size and material

When selecting metal EMC cable glands, the size should be determined based on the diameter of the cable and the requirements of the equipment. In addition, materials suitable for the equipment environment and usage conditions should also be selected, such as stainless steel, aluminum alloy, etc.

2. Determine the wiring direction of the cable

Before installing the metal EMC cable gland, the cable routing direction should be determined to ensure that the cable does not bend or break when passing through the gland.

3. Punch and eliminate burrs

Before punching holes into the equipment shell or plate, carefully measure the position of the hole to be punched according to the specifications of the sealing sleeve. After completing the drilling, the burrs around the hole should also be cleaned to avoid damaging the cable or causing electromagnetic interference.

4. Install the sealing sleeve and tighten it

After threading the cable through the metal EMC cable gland and inserting it into the equipment, the gland should be tightly tightened and a gasket should be placed in the middle to ensure that the gland fits tightly with the equipment casing, preventing external dust, moisture, and other substances from entering the equipment and affecting its normal operation.

5. Make good grounding

After installing the sealing sleeve, it is also necessary to ground the cable to ensure that the equipment meets various safety standards and does not cause any harm to personnel's health.

In summary, installing metal EMC cable glands is a crucial operation. Only by following the correct installation steps can the protective effect of metal EMC cable glands be fully utilized. Therefore, before installation, it is necessary to carefully read the installation manual and ensure that all operations comply with safety and technical requirements.

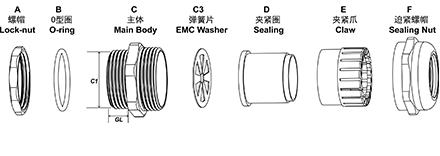

| EMC Metal Cable Gland | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M10*1.0 | M10-6.5 | 3-6.5 | 10 | 6.5 | 14/14 | 50 |

| M12*1.5 | M12-6.5 | 3-6.5 | 12 | 6.5 | 14/14 | 50 |

| M12*1.5 | M12-8 | 4-8 | 12 | 7 | 14/17 | 50 |

| M14*1.5 | M14-8 | 4-8 | 14 | 7 | 17/17 | 50 |

| M16*1.5 | M16-8 | 4-8 | 16 | 8 | 18/18 | 50 |

| M16*1.5 | M16-10 | 5-10 | 16 | 8 | 18/20 | 50 |

| M18*1.5 | M18-10 | 5-10 | 18 | 8 | 20/20 | 50 |

| M20*1.5 | M20-12 | 6-12 | 20 | 8 | 22/22 | 50 |

| M22*1.5 | M22-14 | 10-14 | 22 | 8 | 24/24 | 50 |

| M24*1.5 | M24-14 | 10-14 | 24 | 9 | 27/24 | 50 |

| M25*1.5 | M25-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| M25-16 | 12-16 | 25 | 9 | 27/27 | 50 | |

| M25-18 | 13-18 | 25 | 9 | 27/30 | 50 | |

| M27*1.5(2) | M27-18 | 13-18 | 27 | 9 | 30/30 | 50 |

| M28*1.5(2) | M28-18 | 13-18 | 28 | 9 | 30/30 | 50 |

| M30*1.5(2) | M30-18 | 13-18 | 30 | 9 | 32/30 | 50 |

| M32*1.5(2) | M32-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| M33*1.5(2) | M33-22 | 15-22 | 33 | 10 | 35/35 | 50 |

| M36*1.5(2) | M36-25 | 18-25 | 36 | 10 | 40/40 | 50 |

| M37*1.5(2) | M37-25 | 18-25 | 37 | 10 | 40/40 | 50 |

| M40*1.5(2) | M40-30 | 22-30 | 40 | 11 | 45/45 | 50 |

| M42*1.5(2) | M42-30 | 22-30 | 42 | 11 | 45/45 | 50 |

| M47*1.5(2) | M47-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| M48*1.5(2) | M48-33 | 25-33 | 48 | 11 | 50/52 | 50 |

| M50*1.5(2) | M50-38 | 32-38 | 50 | 13 | 55/57 | 50 |

| M54*1.5(2) | M54-38 | 32-38 | 54 | 13 | 55/57 | 50 |

| M60*1.5(2) | M60-44 | 37-44 | 60 | 14 | 64/64 | 50 |

| M63*1.5(2) | M63-44 | 37-44 | 63 | 14 | 68/64 | 50 |

| M64*1.5(2) | M64-44 | 37-44 | 64 | 14 | 68/64 | 50 |

| M72*1.5(2) | M72-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| M75*1.5(2) | M75-52 | 42-52 | 75 | 16 | 78/78 | 50 |

| M80*1.5(2) | M80-62 | 55-62 | 80 | 18 | 88/88 | 50 |

| M88*1.5(2) | M88-70 | 65-70 | 88 | 18 | 94/94 | 50 |

| M100*1.5(2) | M100-84 | 78-84 | 100 | 20 | 110/110 | 50 |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PG7-6.5 | 3-6.5 | 12.5 | 6.5 | 14/14 | 50 |

| PG9 | PG9-8 | 4-8 | 15.2 | 7 | 17/17 | 50 |

| PG11 | PG11-10 | 5-10 | 18.6 | 8 | 20/20 | 50 |

| PG13.5 | PG13.5-12 | 6-12 | 20.4 | 8 | 22/22 | 50 |

| PG16 | PG16-14 | 10-14 | 22.5 | 9 | 24/24 | 50 |

| PG19 | PG19-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| PG21 | PG21-18 | 13-18 | 28.3 | 9 | 30/30 | 50 |

| PG25 | PG25-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| PG29 | PG29-25 | 18-25 | 37 | 11 | 40/40 | 50 |

| PG36 | PG36-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| PG42 | PG42-38 | 32-38 | 54 | 13 | 57/57 | 50 |

| PG48 | PG48-44 | 37-44 | 59.3 | 14 | 64/64 | 50 |

| PG63 | PG63-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| G | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G1/4 | G1/4 | 3-6.5 | 13.1 | 6 | 14/14 | 50 |

| G3/8 | G3/8 | 4-8 | 16.6 | 8 | 18/18 | 50 |

| G1/2 | G1/2 | 6-12 | 20.9 | 8 | 22/22 | 50 |

| G3/4 | G3/4 | 13-18 | 26.4 | 9 | 30/30 | 50 |

| G1 | G1 | 18-25 | 33.2 | 10 | 40/40 | 50 |

| G1-1/4 | G1-1/4 | 25-33 | 41.9 | 13 | 50/50 | 50 |

| G1-1/2 | G1-1/2 | 32-38 | 47.8 | 14 | 57/57 | 50 |

| G2 | G2 | 37-44 | 59.6 | 14 | 64/64 | 50 |

| G2-1/2 | G2-1/2 | 42-52 | 75.1 | 15 | 77/77 | 50 |

| G3 | G3 | 65-70 | 87.8 | 15 | 94/94 | 50 |

| NPT | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| NPT1/4 | NPT1/4 | 3-6.5 | 13.6 | 6 | 14/14 | 50 |

| NPT3/8 | NPT3/8 | 4-8 | 17 | 8 | 18/18 | 50 |

| NPT1/2 | NPT1/2 | 6-12 | 21.2 | 8 | 22/22 | 50 |

| NPT3/4 | NPT3/4 | 13-18 | 26.5 | 9 | 30/30 | 50 |

| NPT1 | NPT1 | 18-25 | 33.2 | 10 | 40/40 | 50 |

| NPT1-1/4 | NPT1-1/4 | 25-33 | 41.9 | 13 | 50/50 | 50 |

| NPT1-1/2 | NPT1-1/2 | 32-38 | 48 | 14 | 57/57 | 50 |

| NPT2 | NPT2 | 37-44 | 60 | 14 | 64/64 | 50 |

| NPT2-1/2 | NPT2-1/2 | 42-52 | 72.6 | 15 | 77/77 | 50 |

| NPT3 | NPT3 | 65-70 | 88.6 | 15 | 94/94 | 50 |

Metal EMC cable glands are an important device used to protect cables and machines from electromagnetic interference. Its installation is very important, not only related to the service life of the equipment, but also to the safety of personnel. Therefore, when installing metal EMC cable glands, the following points need to be noted:

1. Choose the appropriate size and material

When selecting metal EMC cable glands, the size should be determined based on the diameter of the cable and the requirements of the equipment. In addition, materials suitable for the equipment environment and usage conditions should also be selected, such as stainless steel, aluminum alloy, etc.

2. Determine the wiring direction of the cable

Before installing the metal EMC cable gland, the cable routing direction should be determined to ensure that the cable does not bend or break when passing through the gland.

3. Punch and eliminate burrs

Before punching holes into the equipment shell or plate, carefully measure the position of the hole to be punched according to the specifications of the sealing sleeve. After completing the drilling, the burrs around the hole should also be cleaned to avoid damaging the cable or causing electromagnetic interference.

4. Install the sealing sleeve and tighten it

After threading the cable through the metal EMC cable gland and inserting it into the equipment, the gland should be tightly tightened and a gasket should be placed in the middle to ensure that the gland fits tightly with the equipment casing, preventing external dust, moisture, and other substances from entering the equipment and affecting its normal operation.

5. Make good grounding

After installing the sealing sleeve, it is also necessary to ground the cable to ensure that the equipment meets various safety standards and does not cause any harm to personnel's health.

In summary, installing metal EMC cable glands is a crucial operation. Only by following the correct installation steps can the protective effect of metal EMC cable glands be fully utilized. Therefore, before installation, it is necessary to carefully read the installation manual and ensure that all operations comply with safety and technical requirements.

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

When the isolation line cable enters the fixed head, the copper contact sheet attached in the fixed head can be used to contact the metal isolation network in the cable, and then the interference electromagnetic wave can be guided to the ground wire, so that the electromagnetic wave interference source can be evacuated. It is applied to all outgoing lines requiring anti magnetic wave and achieves

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel.

2.Choosing the correct thread international standard.(Metric,PG,NPT,G).

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread.

1.Question: Can customize long thread of metal cable gland ?

Answer: Yes. The shape and screw length of ordinary metal products can be customized after 3D & CAD drawings are provided without new molds (except for special appearance products).

2.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.Customized model based on the QTY.