Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

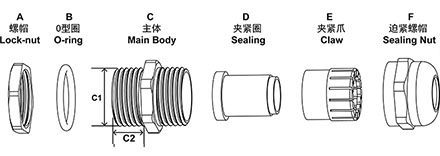

This product is a metal half way cable sealing sleeve, with the main material made of brass nickel plating, the clamping claw made of PA66, and the clamping ring made of nitrile rubber. This product has multiple outstanding advantages and meets international standards. At the same time, this product has passed UL fire protection certification, has high reliability and waterproof performance, strong tensile resistance, and can withstand high temperatures.

The main body of the sealing sleeve is made of brass nickel plating, which has strong rust prevention and corrosion resistance, as well as better thermal conductivity. Its clamping jaws are made of PA66 and have good insulation and wear resistance. The clamping ring is made of nitrile rubber, which has excellent sealing performance and aging resistance, ensuring that the cable will not leak during long-term use.

The characteristic of this product is not only its excellent material quality, but also its excellent performance that meets international standards. Through UL fire certification, this product has high reliability and fire performance, which can effectively prevent cable power failure and fire, and ensure Electrical safety. The product has strong tensile resistance and can withstand high temperatures. It has a wide range of clamping cables and a wide range of applications.

In summary, this product not only has excellent material quality, but also has multiple excellent performance indicators, meeting international standards and UL fire protection certification. It has strong waterproof and tensile resistance, and can operate stably for a long time. Widely used in the electrical field, it is an excellent semi through cable gland with high reliability and safety.

The tightening head, body, and nut are made of copper alloy nickel plated, the clamping claw components are made of UL approved nylon PA66 (fire rating UL94V-2), the clamping ring is made of nitrile rubber, and the gasket is made of black silicone

| Waterproof Brass Cable Gland (Half Through Type) | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M8*0.5 | M8-4.5 | 3-4.5 | 8 | 4 | 11/12 | 50 |

| M10*1.0 | M10-6.5 | 3-6.5 | 10 | 6.5 | 14/14 | 50 |

| M12*1.5 | M12-6.5 | 3-6.5 | 12 | 6.5 | 14/14 | 50 |

| M12-8 | 4-8 | 12 | 7 | 14/17 | 50 | |

| M14*1.5 | M14-8 | 4-8 | 14 | 7 | 17/17 | 50 |

| M16*1.5 | M16-8 | 4-8 | 16 | 8 | 18/18 | 50 |

| M16-10 | 5-10 | 16 | 8 | 18/20 | 50 | |

| M18*1.5 | M18-10 | 5-10 | 18 | 8 | 20/20 | 50 |

| M20*1.5 | M20-12 | 6-12 | 20 | 8 | 22/22 | 50 |

| M22*1.5 | M22-14 | 10-14 | 22 | 8 | 24/24 | 50 |

| M24*1.5 | M24-14 | 10-14 | 24 | 9 | 27/24 | 50 |

| M25*1.5 | M25-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| M25-16 | 12-16 | 25 | 9 | 27/27 | 50 | |

| M25-18 | 13-18 | 25 | 9 | 27/30 | 50 | |

| M27*1.5(2) | M27-18 | 13-18 | 27 | 9 | 30/30 | 50 |

| M28*1.5(2) | M28-18 | 13-18 | 28 | 9 | 30/30 | 50 |

| M30*1.5(2) | M30-18 | 13-18 | 30 | 9 | 32/30 | 50 |

| M32*1.5(2) | M32-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| M33*1.5(2) | M33-22 | 15-22 | 33 | 10 | 35/35 | 50 |

| M36*1.5(2) | M36-25 | 18-25 | 36 | 10 | 40/40 | 50 |

| M37*1.5(2) | M37-25 | 18-25 | 37 | 10 | 40/40 | 50 |

| M40*1.5(2) | M40-30 | 22-30 | 40 | 11 | 45/45 | 50 |

| M42*1.5(2) | M42-30 | 22-30 | 42 | 11 | 45/45 | 50 |

| M47*1.5(2) | M47-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| M48*1.5(2) | M48-33 | 25-33 | 48 | 11 | 50/52 | 50 |

| M50*1.5(2) | M50-38 | 32-38 | 50 | 13 | 55/57 | 50 |

| M54*1.5(2) | M54-38 | 32-38 | 54 | 13 | 55/57 | 50 |

| M60*1.5(2) | M60-44 | 37-44 | 60 | 14 | 64/64 | 50 |

| M63*1.5(2) | M63-44 | 37-44 | 63 | 14 | 68/64 | 50 |

| M64*1.5(2) | M64-44 | 37-44 | 64 | 14 | 68/64 | 50 |

| M72*1.5(2) | M72-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| M75*1.5(2) | M75-52 | 42-52 | 75 | 16 | 78/78 | 50 |

| M80*1.5(2) | M80-62 | 55-62 | 80 | 18 | 88/88 | 50 |

| M88*1.5(2) | M88-70 | 65-70 | 88 | 18 | 94/94 | 50 |

| M100*1.5(2) | M100-84 | 78-84 | 100 | 20 | 110/110 | 50 |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PG7-6.5 | 3-6.5 | 12.5 | 6.5 | 14/14 | 50 |

| PG9 | PG9-8 | 4-8 | 15.2 | 7 | 17/17 | 50 |

| PG11 | PG11-10 | 5-10 | 18.6 | 8 | 20/20 | 50 |

| PG13.5 | PG13.5-12 | 6-12 | 20.4 | 8 | 22/22 | 50 |

| PG16 | PG16-14 | 10-14 | 22.5 | 9 | 24/24 | 50 |

| PG19 | PG19-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| PG21 | PG21-18 | 13-18 | 28.3 | 9 | 30/30 | 50 |

| PG25 | PG25-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| PG29 | PG29-25 | 18-25 | 37 | 11 | 40/40 | 50 |

| PG36 | PG36-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| PG42 | PG42-38 | 32-38 | 54 | 13 | 57/57 | 50 |

| PG48 | PG48-44 | 37-44 | 59.3 | 14 | 64/64 | 50 |

| PG63 | PG63-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| NPT | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| NPT1/4 | NPT1/4 | 3-6.5 | 13.6 | 6 | 14/14 | 50 |

| NPT3/8 | NPT3/8 | 4-8 | 17 | 8 | 18/18 | 50 |

| NPT1/2 | NPT1/2 | 6-12 | 21.2 | 8 | 22/22 | 50 |

| NPT3/4 | NPT3/4 | 13-18 | 26.5 | 9 | 30/30 | 50 |

| NPT1 | NPT1 | 18-25 | 33.2 | 11 | 40/40 | 50 |

| NPT1-1/4 | NPT1-1/4 | 25-33 | 41.9 | 13 | 50/50 | 50 |

| NPT1-1/2 | NPT1-1/2 | 32-38 | 48 | 14 | 57/57 | 50 |

| NPT2 | NPT2 | 37-44 | 60 | 14 | 64/64 | 50 |

| NPT2-1/2 | NPT2-1/2 | 42-52 | 72.6 | 15 | 77/77 | 50 |

| NPT3 | NPT3 | 65-70 | 88.6 | 15 | 94/94 | 50 |

| G | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G1/4 | G1/4 | 3-6.5 | 13.1 | 6 | 14/14 | 50 |

| G3/8 | G3/8 | 4-8 | 16.6 | 8 | 18/18 | 50 |

| G1/2 | G1/2 | 6-12 | 20.9 | 8 | 22/22 | 50 |

| G3/4 | G3/4 | 13-18 | 26.4 | 9 | 30/30 | 50 |

| G1 | G1 | 18-25 | 33.2 | 10 | 40/40 | 50 |

| G1-1/4 | G1-1/4 | 25-33 | 41.9 | 13 | 50/50 | 50 |

| G1-1/2 | G1-1/2 | 32-38 | 47.8 | 14 | 57/57 | 50 |

| G2 | G2 | 37-44 | 59.6 | 14 | 64/64 | 50 |

| G2-1/2 | G2-1/2 | 42-52 | 75.1 | 15 | 77/77 | 50 |

| G3 | G3 | 65-70 | 87.8 | 15 | 94/94 | 50 |

The metal cable gland is an important accessory used to protect the wiring and prevent pollutants such as rainwater and dust from entering the interior of the cable, thus protecting the cable. The following are the installation precautions for metal cable glands:

1. Select appropriate specifications and models of sealing sleeves. Adopting the correct sealing sleeve model is a prerequisite for ensuring installation quality.

2. Make sufficient preparations for the installation of metal cable glands, including organizing cables, removing dust from cable surfaces, preparing connection paths and tools, and so on.

When installing the sealing sleeve, different methods should be used according to different situations. Usually, liquid injection or mechanical compression methods can be used to fully seal and ensure installation effectiveness.

4. During the installation process, cables should be fully protected to avoid damage. During installation, it is necessary to ensure complete contact between the cable end and the sealing sleeve, eliminate air bubbles, and fully inject or compact the liquid.

5. When installing the sealing sleeve, it is necessary to control the surrounding temperature and humidity to avoid related diseases that may cause poor installation.

The above are the installation precautions for metal cable glands. Everyone must pay attention to details during the installation process to ensure installation quality.

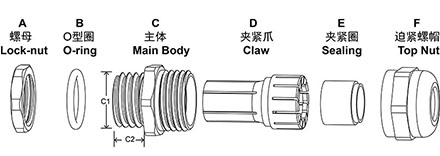

The metal straight through cable gland is a reliable sealing device with a main material made of brass nickel plating. It has good corrosion resistance and conductivity, and can effectively prevent cable oxidation and corrosion. Clamping claw and clamping ring are made of PA66 and NBR respectively, which have excellent resistance to high temperature, abrasion and aging, and can effectively maintain the stability and reliability of the cable.

The gasket is made of black silicone, which has good elasticity and durability, effectively preventing moisture and dust from entering the interior of the cable, ensuring the transmission efficiency and safety of the cable. At the same time, the sealing sleeve made of brass nickel plating has good high-temperature resistance, which can withstand the pressure and tension in high-temperature environments, ensuring the stable transmission and durability of the cable.

The metal straight through cable gland has passed UL fire protection certification and has good fire and explosion protection performance, effectively protecting the cable from dangerous factors such as fire and explosion. At the same time, the clamping range of the sealing sleeve is wide, suitable for cables of different diameters and sizes, and has strong adaptability and flexibility.

In summary, the metal straight through cable sealing sleeve has advantages such as waterproofing, strong tensile resistance, and high temperature resistance, and can be widely used in fields such as power, construction, communication, machinery, etc., providing reliable guarantees for the safe transmission of protective cables.

The tightening head, body, and nut are made of copper alloy nickel plated, the clamping claw components are made of UL approved nylon PA66 (fire rating UL94V-2), the clamping ring is made of nitrile rubber, and the gasket is made of black silicone

| Waterproof Brass Cable Gland (Straight Through Type) | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M8*0.5 | M8-4.5 | 3-4.5 | 8 | 4 | 11/12 | 50 |

| M10*1.0 | M10-6.5 | 3-6.5 | 10 | 6.5 | 14/14 | 50 |

| M12*1.5 | M12-6.5 | 3-6.5 | 12 | 6.5 | 14/14 | 50 |

| M12-8 | 4-8 | 12 | 7 | 14/17 | 50 | |

| M14*1.5 | M14-8 | 4-8 | 14 | 7 | 17/17 | 50 |

| M16*1.5 | M16-8 | 4-8 | 16 | 8 | 18/18 | 50 |

| M16-10 | 5-10 | 16 | 8 | 18/20 | 50 | |

| M18*1.5 | M18-10 | 5-10 | 18 | 8 | 20/20 | 50 |

| M20*1.5 | M20-12 | 6-12 | 20 | 8 | 22/22 | 50 |

| M22*1.5 | M22-14 | 10-14 | 22 | 8 | 24/24 | 50 |

| M24*1.5 | M24-14 | 10-14 | 24 | 9 | 27/24 | 50 |

| M25*1.5 | M25-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| M25-16 | 12-16 | 25 | 9 | 27/27 | 50 | |

| M25-18 | 13-18 | 25 | 9 | 27/30 | 50 | |

| M27*1.5(2) | M27-18 | 13-18 | 27 | 9 | 30/30 | 50 |

| M28*1.5(2) | M28-18 | 13-18 | 28 | 9 | 30/30 | 50 |

| M30*1.5(2) | M30-18 | 13-18 | 30 | 9 | 32/30 | 50 |

| M32*1.5(2) | M32-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| M33*1.5(2) | M33-22 | 15-22 | 33 | 10 | 35/35 | 50 |

| M36*1.5(2) | M36-25 | 18-25 | 36 | 10 | 40/40 | 50 |

| M37*1.5(2) | M37-25 | 18-25 | 37 | 10 | 40/40 | 50 |

| M40*1.5(2) | M40-30 | 22-30 | 40 | 11 | 45/45 | 50 |

| M42*1.5(2) | M42-30 | 22-30 | 42 | 11 | 45/45 | 50 |

| M47*1.5(2) | M47-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| M48*1.5(2) | M48-33 | 25-33 | 48 | 11 | 50/52 | 50 |

| M50*1.5(2) | M50-38 | 32-38 | 50 | 13 | 55/57 | 50 |

| M54*1.5(2) | M54-38 | 32-38 | 54 | 13 | 55/57 | 50 |

| M60*1.5(2) | M60-44 | 37-44 | 60 | 14 | 64/64 | 50 |

| M63*1.5(2) | M63-44 | 37-44 | 63 | 14 | 68/64 | 50 |

| M64*1.5(2) | M64-44 | 37-44 | 64 | 14 | 68/64 | 50 |

| M72*1.5(2) | M72-52 | 42-52 | 72 | 16 | 78/78 | 50 |

| M75*1.5(2) | M75-52 | 42-52 | 75 | 16 | 78/78 | 50 |

| M80*1.5(2) | M80-62 | 55-62 | 80 | 18 | 88/88 | 50 |

| M88*1.5(2) | M88-70 | 65-70 | 88 | 18 | 94/94 | 50 |

| M100*1.5(2) | M100-84 | 78-84 | 100 | 20 | 110/110 | 50 |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PG7-6.5 | 3-6.5 | 12.5 | 6.5 | 14/14 | 50 |

| PG9 | PG9-8 | 4-8 | 15.2 | 7 | 17/17 | 50 |

| PG11 | PG11-10 | 5-10 | 18.6 | 8 | 20/20 | 50 |

| PG13.5 | PG13.5-12 | 6-12 | 20.4 | 8 | 22/22 | 50 |

| PG16 | PG16-14 | 10-14 | 22.5 | 9 | 24/24 | 50 |

| PG19 | PG19-14 | 10-14 | 25 | 9 | 27/24 | 50 |

| PG21 | PG21-18 | 13-18 | 28.3 | 9 | 30/30 | 50 |

| PG25 | PG25-22 | 15-22 | 32 | 10 | 35/35 | 50 |

| PG29 | PG29-25 | 18-25 | 37 | 11 | 40/40 | 50 |

| PG36 | PG36-33 | 25-33 | 47 | 11 | 50/50 | 50 |

| PG42 | PG42-38 | 32-38 | 54 | 13 | 57/57 | 50 |

| PG48 | PG48-44 | 37-44 | 59.3 | 14 | 64/64 | 50 |

| PG63 | PG63-52 | 42-52 | 72 | 16 | 78/78 | 50 |

The metal cable gland is an important accessory used to protect the wiring and prevent pollutants such as rainwater and dust from entering the interior of the cable, thus protecting the cable. The following are the installation precautions for metal cable glands:

1. Select appropriate specifications and models of sealing sleeves. Adopting the correct sealing sleeve model is a prerequisite for ensuring installation quality.

2. Make sufficient preparations for the installation of metal cable glands, including organizing cables, removing dust from cable surfaces, preparing connection paths and tools, and so on.

When installing the sealing sleeve, different methods should be used according to different situations. Usually, liquid injection or mechanical compression methods can be used to fully seal and ensure installation effectiveness.

4. During the installation process, cables should be fully protected to avoid damage. During installation, it is necessary to ensure complete contact between the cable end and the sealing sleeve, eliminate air bubbles, and fully inject or compact the liquid.

5. When installing the sealing sleeve, it is necessary to control the surrounding temperature and humidity to avoid related diseases that may cause poor installation.

The above are the installation precautions for metal cable glands. Everyone must pay attention to details during the installation process to ensure installation quality.

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

1.Installation time: A type needs 10-15s,B type needs 5-10s

2.Protection degree: IP68-10

3.Both A & B type are easier for installation .A type structure is the updated design based on the B type ,and easier installation and removal.

|

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel. |

2.Choosing the correct thread international standard.(Metric,PG,NPT,G). |

3.If there is no tapping hole on the mounting panel , you can choose any type of thread . |

1.Question: Can customize long thread of metal cable gland ?

Answer: Yes. The shape and screw length of ordinary metal products can be customized after 3D & CAD drawings are provided without new molds (except for special appearance products).

2.Question:Does the signal lamp affect the magnetic field?

Answer:This product can also be used with armor wires to achieve the purpose of EMC anti-magnetic wave.

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.Customized model based on the QTY.