Nylon bellow is a material with elasticity, wear resistance, and corrosion resistance, used to protect the moving parts of various mechanical equipment from entering pollutants such as dust, water vapor, and oil stains. Its main function is to protect mechanical equipment from damage from the external environment during movement, ensuring the normal operation of the mechanical equipment.

Nylon Bellow is light in weight, has corrosion resistance and compressibility resistance, and has good elasticity and wear resistance. Therefore, it is widely used in mechanical manufacturing industries such as automobile manufacturing, machine tools, elevators, packaging machinery, medical equipment, etc. The following is a detailed description of the characteristics of Nylon Bellow:

1. Economical and practical: Nylon Bellow has a long service life, which can protect moving parts to a certain extent, effectively reduce equipment failures, improve equipment service life, and become more economical and practical;

2. High temperature resistance: Nylon Bellow can withstand high temperatures and can be used in high-temperature environments, making it suitable for protecting equipment used in some high-temperature environments;

3. Good corrosion resistance: Nylon Bellow has excellent resistance to rust and corrosion, maintaining its original shape and luster, thereby effectively extending its service life;

4. Strong pressure resistance: Nylon Bellow has strong pressure resistance, which can resist the forces generated by sliding and protect moving parts;

5. Dust and dirt prevention: Nylon Bellow has a smooth surface that does not absorb dust or water mist, making it effective in dust prevention and protection under different environmental conditions.

In addition to the above characteristics, Nylon Bellow also has the following advantages:

1. Easy to install: Nylon Bellow is simple and convenient to install, and can be made of different materials, lengths, or shapes according to needs, widely used on different mechanical equipment;

2. It will not cause any damage to the mechanical equipment, and will not have any impact on the trajectory and movement of the mechanical equipment, thereby reducing the failure rate caused by the use of nylon bell;

3. The purchase cost is low, and using Nylon Bellow to protect mechanical equipment is very affordable. This low-cost protection measure can effectively extend the service life of mechanical equipment and improve equipment efficiency.

Overall, Nylon Bellow has many advantages and can be used to protect various mechanical equipment, ensure its normal operation, and extend its service life. At the same time, replacing the nylon bell is a low-cost maintenance method, and its superiority is widely recognized and applied in the market.

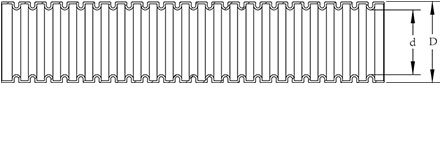

| Nylon Corrugated Tubings | |||||

| Cat. No. | Size | Curved Radius (mm) |

Std.pkg (Mts/Roll) |

||

| Inch | I.D.(mm) | O.D.(mm) | |||

| AD-10 | 1/4 | 6.5 | 10.0 | 10 | 100 |

| AD13 | 5/16 | 10.0 | 13.0 | 10 | 100 |

| AD15.8 | 3/8 | 12.0 | 15.8 | 10 | 100 |

| AD18.5 | 14.3 | 18.5 | 10 | 100 | |

| AD21.2 | 1/2 | 17.0 | 21.2 | 12.5 | 100 |

| AD25 | 20.0 | 25.0 | 12.5 | 50 | |

| AD28.5 | 3/4 | 23.0 | 28.5 | 10 | 50 |

| AD34.5 | 1 | 29.0 | 34.5 | 10 | 50 |

| AD42.5 | 1 1/4 | 36.0 | 42.5 | 13 | 50 |

| AD54.5 | 2 | 48.0 | 54.5 | 13 | 25 |

| Diference and apllication of PA,PP,PE | |||||||

| Product | PA | PP | PE | ||||

| Product material: | Nylon PA66 | Polypropylene | Polyethylene | ||||

| Working temperature | -40℃~125℃; in state instaneous heat resistance up to 150℃ |

-30℃~100℃; in state instaneous heat resistance up to 140℃ |

-30℃~100℃; in state instaneous heat resistance up to 120℃ |

||||

| Flame retardant | Not flame retardant | Flame retardant and Not flame retardant |

Flame retardant and Not flame retardant |

||||

| Sturcture | Both internal and external waves | ||||||

| Features | Good flexibility, anti-twist, good bending performance; acid resistance, lubricating oil, cooling liquid, etc., bright surface gloss, friction resistance | Good flexibility, surface gloss, chemical resistance | Good flexibility, surface gloss, chemical resistance | ||||

| Carrying Capacity | Can withstand the heavy pressure of the foot, not broken, not deformed, can be recovered quickly, and itself without any damage | Harder than PE bellows and softer than PA | The softer one, it can be squashed by hand | ||||

| Application field | Machinery manufacturing, electrical insulation protection, lighting equipment, automobile manufacturing, aviation equipment, subway, train, automation control and other industries | It is mainly used for automobile wiring, and can also be used for machine tool machinery, automatic instruments, motors and motors, protecting cables and wires from external forces and insulation; | It can be used in machine tool machinery, electrical equipment, food machinery, automation equipment | ||||

1.Question: can i print our own logo on product packing ?

Answer: Of course.we are a professional manufacturing with over 10 years of OEM exprience,Customer's LOGO can be produced by laser, embossing, printing, etc.

2.Question: How long is the working life of cable gland?

Answer:More than 10 years undaer normal environment.

3.Question: what is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.

4.Question: If we buy your product and find quality problems, how to solve it?

Answer: If quality problems are caused by us instead of external reasons, we will compensate each item to the customer.

5.Question: Can be accept OEM color & packing of flexible corrguated pipe?

Answer: Yes,OEM,ODM can be accepted.