Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

The metal Multi Hole cable gland is a high-quality cable gland certified by UL fire protection. This sealing sleeve has various advantages such as fire resistance, waterproofing, strong tensile resistance, high temperature resistance, and wide clamping range of cables, making it suitable for sealing and protecting various industrial and civil cables.

The cable gland adopts a metal multi hole design, which can effectively seal and protect the cable, and can maintain its original performance in high temperature and harsh environments. This sealing sleeve meets UL fire safety certification and has extremely high fire resistance performance, which can effectively reduce the risk of fire occurrence.

At the same time, the metal multi hole cable gland has excellent waterproof performance, which can prevent moisture and moisture from entering the interior of the cable, thereby protecting the safe and stable operation of the cable system. At the same time, the tensile performance of the sealing sleeve is very strong, which can withstand large tensile forces, thereby ensuring the safety performance of the cable system.

In addition, the sealing sleeve is also very high-temperature resistant and can work stably for a long time in high-temperature environments without losing its performance. At the same time, it has a wide range of clamping cables and can be applied to various different specifications of cables, thus having a wide range of applications.

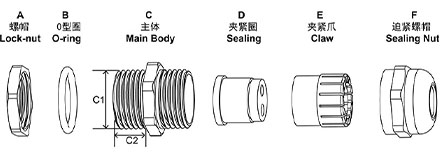

A. C and F parts are made of copper alloy nickel plating, the clamping claw part is made of UL approved nylon PA66 (fire rating UL94V-2), the clamping ring, and the O-ring part is made of nitrile rubber

|

Multiple Brass Cable Gland Metric / PG / G / NPT |

|||||||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

M12-H2 | M12*1.5 | 3-1.2 | 12 | 7 | 14 | |

| M16-H2 | M16*1.5 | 4-1.6 | 16 | 8 | 18 | ||

| M18-H2 | M18*1.5 | 3.5-2 | 18 | 8 | 20 | ||

| M20A-H2 | M20*1.5 | 5.3-1.5 | 20 | 8 | 22 | ||

| M20B-H2 | M20*1.5 | 3.5-2 | 20 | 8 | 22 | ||

| M22-H2 | M22*1.5 | 6-2.5 | 22 | 8 | 24 | ||

| M25-H2 | M25*1.5 | 8.7-4 | 25 | 9 | 30 | ||

| M32-H2 | M32*1.5 | 10-5 | 32 | 9 | 35 | ||

| PG7-H2 | PG7 | 3-1.2 | 12.5 | 8 | 14 | ||

| PG9-H2 | PG9 | 4-1.6 | 15.2 | 8 | 17 | ||

| PG11-H2 | PG11 | 3.5-2 | 18.6 | 8 | 20 | ||

| PG13.5-H2 | PG13.5 | 5.3-1.5 | 20.4 | 8 | 22 | ||

| PG16-H2 | PG16 | 6-2.5 | 22.5 | 8 | 24 | ||

| PG21-H2 | PG21 | 8.7-4.5 | 28.3 | 9 | 30 | ||

| PG29-H2 | PG29 | 10-5 | 37 | 10 | 40 | ||

| G1/4-H2 | G1/4 | 3-1.2 | 13.1 | 7 | 14 | ||

| G3/8-H2 | G3/8 | 4-1.6 | 16.6 | 8 | 18 | ||

| G1/2A-H2 | G1/2 | 3.5-2 | 20.9 | 8 | 22 | ||

| G1/2B-H2 | G1/2 | 5.3-1.5 | 20.9 | 8 | 22 | ||

| G3/4-H2 | G3/4 | 8.7-4.5 | 26.4 | 9 | 30 | ||

| G1-H2 | G1 | 10-5 | 33.2 | 10 | 35 | ||

| N3/8-H2 | NPT3/8 | 4-1.6 | 17 | 8 | 18 | ||

| N1/2A-H2 | NPT1/2 | 3.5-2 | 21.2 | 8 | 22 | ||

| N1/2B-H2 | NPT1/2 | 5.3-1.5 | 21.2 | 8 | 22 | ||

| N3/4-H2 | NPT3/4 | 8.7-4.5 | 26.5 | 9 | 30 | ||

| N1-H2 | NPT1 | 10-5 | 33.2 | 10 | 35 | ||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

M12-H3 | M12*1.5 | 2.6-1.2 | 12 | 7 | 14 | |

| M16-H3 | M16*1.5 | 2.6-1.2 | 16 | 8 | 18 | ||

| M18-H3 | M18*1.5 | 4-1.6 | 18 | 8 | 20 | ||

| M20A-H3 | M20*1.5 | 5-2 | 20 | 8 | 22 | ||

| M20B-H3 | M20*1.5 | 3.5-1.5 | 20 | 8 | 22 | ||

| M22-H3 | M22*1.5 | 3.5-1.5 | 22 | 8 | 24 | ||

| M25-H3 | M25*1.5 | 8-4 | 25 | 9 | 30 | ||

| M32-H3 | M32*1.5 | 10-5 | 32 | 9 | 35 | ||

| PG7-H3 | PG7 | 2.6-1.2 | 12.5 | 8 | 14 | ||

| PG9-H3 | PG9 | 2.6-1.2 | 15.2 | 8 | 17 | ||

| PG11-H3 | PG11 | 4-1.6 | 18.6 | 8 | 20 | ||

| PG13.5-H3 | PG13.5 | 5-2 | 20.4 | 8 | 22 | ||

| PG16-H3 | PG16 | 3.5-1.5 | 22.5 | 8 | 24 | ||

| PG21-H3 | PG21 | 5-2 | 28.3 | 9 | 30 | ||

| PG29-H3 | PG29 | 10-5 | 37 | 10 | 40 | ||

| G1/4-H3 | G1/4 | 2.6-1.2 | 13.1 | 7 | 14 | ||

| G3/8-H3 | G3/8 | 4-1.6 | 16.6 | 8 | 18 | ||

| G1/2A-H3 | G1/2 | 5-2 | 20.9 | 8 | 22 | ||

| G1/2B-H3 | G1/2 | 3.5-1.5 | 20.9 | 8 | 22 | ||

| G3/4-H3 | G3/4 | 8-4 | 26.4 | 9 | 30 | ||

| G1-H3 | G1 | 10-5 | 33.2 | 10 | 35 | ||

| N3/8-H3 | NPT3/8 | 4-1.6 | 17 | 8 | 18 | ||

| N1/2A-H3 | NPT1/2 | 3.5-1.5 | 21.2 | 8 | 22 | ||

| N1/2B-H3 | NPT1/2 | 5-2 | 21.2 | 8 | 22 | ||

| N3/4-H3 | NPT3/4 | 8-4 | 26.5 | 9 | 30 | ||

| N1-H3 | NPT1 | 10-5 | 33.2 | 10 | 35 | ||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

M12-H4 | M12*1.5 | 2.3-1 | 12 | 7 | 14 | |

| M16-H4 | M16*1.5 | 2.3-1 | 16 | 8 | 18 | ||

| M18-H4 | M18*1.5 | 3-1.2 | 18 | 8 | 20 | ||

| M20A-H4 | M20*1.5 | 4.2-1.7 | 20 | 8 | 22 | ||

| M20B-H4 | M20*1.5 | 3.5-1.5 | 20 | 8 | 22 | ||

| M22-H4 | M22*1.5 | 4.5-2 | 22 | 8 | 24 | ||

| M25-H4 | M25*1.5 | 5-2 | 25 | 9 | 30 | ||

| M32-H4 | M32*1.5 | 9-4.5 | 32 | 9 | 35 | ||

| PG7-H4 | PG7 | 2.3-1 | 12.5 | 8 | 14 | ||

| PG9-H4 | PG9 | 2.3-1 | 15.2 | 8 | 17 | ||

| PG11-H4 | PG11 | 3-1.2 | 18.6 | 8 | 20 | ||

| PG13.5-H4 | PG13.5 | 4.2-1.7 | 20.4 | 8 | 22 | ||

| PG16-H4 | PG16 | 4.5-2 | 22.5 | 8 | 24 | ||

| PG21-H4 | PG21 | 7-3.5 | 28.3 | 9 | 30 | ||

| PG29-H4 | PG29 | 9-4.5 | 37 | 10 | 40 | ||

| G1/4-H4 | G1/4 | 2.3-1 | 13.1 | 7 | 14 | ||

| G3/8-H4 | G3/8 | 3-1.2 | 16.6 | 8 | 18 | ||

| G1/2A-H4 | G1/2 | 3.5-1.5 | 20.9 | 8 | 22 | ||

| G1/2B-H4 | G1/2 | 4.5-2 | 20.9 | 8 | 22 | ||

| G3/4-H4 | G3/4 | 7-3.5 | 26.4 | 9 | 30 | ||

| G1-H4 | G1 | 9-4.5 | 33.2 | 10 | 35 | ||

| N3/8-H4 | NPT3/8 | 2.3-1 | 17 | 8 | 18 | ||

| N1/2A-H4 | NPT1/2 | 3.5-1.5 | 21.2 | 8 | 22 | ||

| N1/2B-H4 | NPT1/2 | 4.5-2 | 21.2 | 8 | 22 | ||

| N3/4-H4 | NPT3/4 | 7-3.5 | 26.5 | 9 | 30 | ||

| N1-H4 | NPT1 | 9-4.5 | 33.2 | 10 | 35 | ||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

M16-H5 | M16*1.5 | 2.5-1 | 16 | 8 | 18 | |

| M20A-H5 | M20*1.5 | 3-1.2 | 20 | 8 | 22 | ||

| M20B-H5 | M20*1.5 | 4.2-1.7 | 20 | 8 | 22 | ||

| M25A-H5 | M25*1.5 | 3.5-1.5 | 25 | 9 | 30 | ||

| M25B-H5 | M25*1.5 | 6-3 | 25 | 9 | 30 | ||

| M32-H5 | M32*1.5 | 8-4 | 32 | 9 | 35 | ||

| PG9-H5 | PG9 | 2.5-1 | 15.2 | 8 | 17 | ||

| PG13.5A-H5 | PG13.5 | 3-1.2 | 20.4 | 8 | 22 | ||

| PG13.5B-H5 | PG13.5 | 4.2-1.7 | 20.4 | 8 | 22 | ||

| PG21A-H5 | PG21 | 3.5-1.5 | 28.3 | 9 | 30 | ||

| PG21B-H5 | PG21 | 6-3 | 28.3 | 9 | 30 | ||

| PG29-H5 | PG29 | 8-4 | 37 | 10 | 40 | ||

| G3/8-H5 | G3/8 | 2.5-1 | 16.6 | 8 | 18 | ||

| G1/2A-H5 | G1/2 | 3-1.2 | 20.9 | 8 | 22 | ||

| G1/2B-H5 | G1/2 | 4.2-17 | 20.9 | 8 | 22 | ||

| G3/4-H5 | G3/4 | 6-3 | 26.4 | 9 | 30 | ||

| G1-H5 | G1 | 8-4 | 33.2 | 10 | 35 | ||

| N3/8-H5 | NPT3/8 | 2.5-1 | 17 | 8 | 18 | ||

| N1/2A-H5 | NPT1/2 | 3-1.2 | 21.2 | 8 | 22 | ||

| N1/2B-H5 | NPT1/2 | 4.2-1.7 | 21.2 | 8 | 22 | ||

| N3/4-H5 | NPT3/4 | 6-3 | 26.5 | 9 | 30 | ||

| N1-H5 | NPT1 | 8-4 | 33.2 | 10 | 35 | ||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

M32-H6 | M32*1.5 | 7-3.5 | 32 | 9 | 35 | |

| PG9-H6 | PG9 | 2-1 | 15.2 | 8 | 17 | ||

| PG13.5-H6 | PG13.5 | 3-1.2 | 20.4 | 8 | 22 | ||

| PG21A-H6 | PG21 | 3.5-1.5 | 28.3 | 9 | 30 | ||

| PG21B-H6 | PG21 | 5.3-2.4 | 28.3 | 9 | 30 | ||

| PG29-H6 | PG29 | 7-3.5 | 37 | 10 | 40 | ||

| G3/8-H6 | G3/8 | 2-1 | 16.6 | 8 | 18 | ||

| G1/2-H6 | G1/2 | 3-1.2 | 20.9 | 8 | 22 | ||

| G3/4A-H6 | G3/4 | 3.5-1.5 | 26.4 | 9 | 30 | ||

| G3/4B-H6 | G3/4 | 5.3-2.4 | 26.4 | 9 | 30 | ||

| G1-H6 | G1 | 7-3.5 | 33.2 | 10 | 35 | ||

| N3/8-H6 | NPT3/8 | 2-1 | 17 | 8 | 18 | ||

| N1/2A-H6 | NPT1/2 | 3-1.2 | 21.2 | 8 | 22 | ||

| N3/4-H6 | NPT3/4 | 3.5-1.5 | 26.5 | 8 | 22 | ||

| N3/4-H6 | NPT3/4 | 5.3-2.4 | 26.5 | 9 | 30 | ||

| N1-H6 | NPT1 | 7-3.5 | 33.2 | 10 | 35 | ||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

M32-H7 | M32*1.5 | 7-3.5 | 32 | 9 | 35 | |

| PG13.5-H7 | PG13.5 | 3-1.2 | 20.4 | 8 | 22 | ||

| PG21-H7 | PG21 | 3.5-1.5 | 28.3 | 9 | 30 | ||

| PG29-H7 | PG29 | 6-3 | 37 | 10 | 40 | ||

| G1/2-H7 | G1/2 | 3-1.2 | 20.9 | 8 | 22 | ||

| G3/4-H7 | G3/4 | 3.5-1.5 | 26.4 | 9 | 30 | ||

| G1-H7 | G1 | 6-3 | 33.2 | 10 | 35 | ||

| N1/2-H7 | NPT1/2 | 3-1.2 | 21.2 | 8 | 22 | ||

| N3/4-H7 | NPT3/4 | 3.5-1.5 | 26.5 | 8 | 30 | ||

| N1-H7 | NPT1 | 6-3 | 33.2 | 10 | 35 | ||

| Model | Part No. | Thread | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

|

|

G1/2-H8 | G1/2 | 2.8-1 | 20.9 | 8 | 22 | |

| G3/4-H8 | G3/4 | 3.5-1.5 | 26.4 | 9 | 30 | ||

| PG13.5-H8 | PG13.5 | 2.8-1 | 20.4 | 8 | 22 | ||

| PG21-H8 | PG21 | 3.5-1.5 | 28.3 | 9 | 30 | ||

| N1/2-H8 | NPT1/2 | 2.8-1 | 21.2 | 8 | 22 | ||

| N3/4-H8 | NPT3/4 | 3.5-1.5 | 26.5 | 8 | 30 | ||

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel.

2.Choosing the correct thread international standard.(Metric,PG,NPT,G).

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread .

4.Long thread type of cable gland is required by the thickness of mounting panel .

1.Question: Can customize long thread of metal cable gland ?

Answer: Yes. The shape and screw length of ordinary metal products can be customized after 3D & CAD drawings are provided without new molds (except for special appearance products).

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.Customized model based on the QTY.