Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

Metal spiral cable gland is a product that can effectively protect cables. In various applications, cables also require corresponding flexibility due to the need to connect different devices that need to be moved, folded, and rotated between them. The metal spiral cable sealing sleeve comes in handy in this situation. By protecting the metal tube access hole and cable, the cable is not easily damaged even under extreme deformation, which can ensure the stable operation of the equipment.

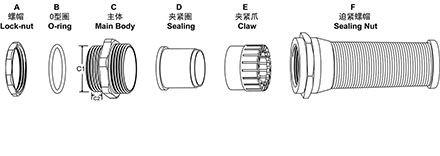

The metal spiral cable gland is composed of many small circular metal sheets, whose elasticity can help them automatically adapt to different shapes and sizes of cables, thus achieving more precise protection. Install sealing rings and screws at both ends of the sealing sleeve to ensure mutual connection between the sealing sleeve and the metal pipe and secure protection of the cable. In this way, not only can it achieve good sealing effect, but it can also withstand various external environmental interference, and the reliability is even more outstanding.

The metal spiral cable sealing sleeve is suitable for handling a wide range of cables, especially suitable for mechanical equipment and forced transmission systems that are very common in industrial production. These systems apply a large number of cables, each of which needs to undergo different durability tests, requiring metal spiral cable glands to have high wear resistance and impact resistance in order to ensure their service life and stability in efficiency.

Overall, metal spiral cable glands are a powerful product for protecting cables. It not only provides good protection for cables, but also resists various external interference. This makes it highly reliable and very convenient to use in various applications. For mechanical equipment and industrial production, this type of cable gland is like a protective shell and is indispensable.

| Flex Protecting Brass Cable Gland | |||||

| Metric | |||||

| Thread | Part No. | Cable Range φ(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M12 | M12*1.5 | 3-6.5 | 6 | 14 | 50 |

| M6 | M16*1.5 | 4-8 | 6 | 18 | 50 |

| M18 | M18*1.5 | 5-10 | 6 | 20 | 50 |

| M20 | M20*1.5 | 6-12 | 6.5 | 22 | 50 |

| M25 | M25*1.5 | 12-16 | 7 | 28 | 50 |

| PG | |||||

| Thread | Part No. | Cable Range φ(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PG7 | 3-6.5 | 5 | 14 | 50 |

| PG9 | PG9 | 4-8 | 6 | 18 | 50 |

| PG11 | PG11 | 5-10 | 6 | 20 | 50 |

| PG13.5 | PG13.5 | 6-12 | 6.5 | 22 | 50 |

| PG16 | PG16 | 10-14 | 6.5 | 24 | 50 |

| PG21 | PG21 | 13-18 | 7 | 30 | 50 |

| G | |||||

| Thread | Part No. | Cable Range φ(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G1/4 | G1/4 | 3-6.5 | 6 | 14 | 50 |

| G3/8 | G3/8 | 4-8 | 7 | 18 | 50 |

| G1/2 | G1/2 | 6-12 | 8 | 22 | 50 |

| G3/4 | G3/4 | 12-16 | 11 | 28 | 50 |

| NPT | |||||

| Thread | Part No. | Cable Range φ(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| NPT1/4 | NPT1/4 | 3-6.5 | 6 | 14 | 50 |

| NPT3/8 | NPT3/8 | 4-8 | 7 | 18 | 50 |

| NPT1/2 | NPT1/2 | 6-12 | 8 | 22 | 50 |

| NPT3/4 | NPT3/4 | 12-16 | 11 | 28 | 50 |

Metal anti bending cable gland is a device for protecting cables, which can effectively prevent cable breakage and damage during the bending process, improve the service life and safety performance of the cable. When installing metal anti bending cable glands, the following points should be noted:

1. Selection of installation location: A suitable installation location should be selected based on the actual situation on site, fully considering the bending radius of the cable and the space limitations of installation, to ensure the feasibility and practicality of the installation location.

2. Preparation before installation: Before installation, the cable should be cleaned and inspected to ensure that the external surface of the cable is smooth and undamaged, and free from dust and loose substances, in order to avoid affecting the installation effect of the sealing sleeve and the normal use of the cable.

3. Sealing sleeve installation: Slide the sealing sleeve along the axial direction of the cable until the sleeve covers the cable bend, then adjust the nuts at both ends of the sealing sleeve to the appropriate position and tighten with a wrench. It should be noted that the tightening force should be appropriate and should not be too tight or loose.

4. Sealing sleeve protection: After installing the sealing sleeve, corresponding protective measures should be taken, such as applying rust inhibitor and anti-corrosion paint, to prevent the sealing sleeve from being corroded and worn, thereby affecting the protective effect of the cable.

5. Safety precautions: During the installation process, always pay attention to safety precautions, such as wearing safety helmets and gloves, to prevent accidents from occurring.

In summary, when installing metal anti bending cable glands, full consideration should be given to the actual situation and strict adherence to installation instructions should be followed to ensure installation quality and safe operation of the cable. At the same time, the sealing sleeve should also be regularly inspected and maintained to ensure its long-term effective protection of the cable.

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel.

2.Choosing the correct thread international standard.(Metric,PG,NPT,G).

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread .

4.Long thread type of cable gland is required by the thickness of mounting panel .

1.Question: Can customize long thread of metal cable gland ?

Answer: Yes. The shape and screw length of ordinary metal products can be customized after 3D & CAD drawings are provided without new molds (except for special appearance products).

2.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.Customized model based on the QTY.