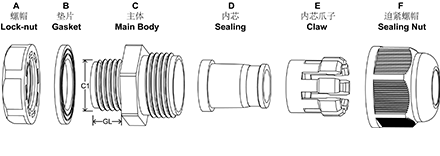

Nylon A-type Divided Body cable gland is a high-performance cable sealing accessory mainly used for sealing the joints of wires and cables, which can effectively prevent moisture, dust, and other external environments from corroding and damaging the cable. The sealing sleeve is made of nylon PA66 material, which has excellent physical and chemical properties and is widely used in industrial control, aerospace, mechanical manufacturing, automotive manufacturing, electronic information and other fields.

The cable gland is designed with a split structure, which is easy to install and can be easily installed outside the cable, saving installation time and cost. At the same time, the sealing sleeve has very high fire resistance, has passed UL fire certification, is of reliable quality, and fully meets environmental requirements in Europe and the United States. This enables it to operate reliably under various harsh working and environmental conditions.

In addition, the cable gland also has the advantages of waterproofing and strong tensile resistance. Its waterproof performance is very excellent, which can effectively prevent water from seeping into the interior of the cable and maintain its stable operation. At the same time, the sealing sleeve is made of high-strength nylon material, which has excellent properties such as high temperature resistance, strong tensile resistance, and wear resistance, and can withstand various harsh environments and working conditions.

In summary, the nylon A-type split cable gland has various advantages such as easy installation, waterproof, strong tensile resistance, and high temperature resistance, fully meeting the application requirements of cable glands. It is widely used at the joints of various wires and cables to protect cables and extend their lifespan.

| Nylon Cable Gland (A Type Divided Body) | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range φ(mm) |

Thread O.D C1(mm) |

Thread Length GL(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M12*1.5 | MGA12-5.5 | 3-6.5 | 12 | 8.5 | 18/19 | 50 |

| MGA12-08 | 4-8 | 12 | 8.5 | 18/19 | 50 | |

| M16*1.5 | MGA16-7-ST | 4-7 | 16 | 10 | 22/22 | 50 |

| MGA16-10-ST | 6-10 | 16 | 10 | 22/22 | 50 | |

| MGA16L-7 | 4-7 | 16 | 15 | 22/22 | 50 | |

| MGA16L-10 | 6-10 | 16 | 15 | 22/22 | 50 | |

| M20*1.5 | MGA20-11-ST | 6-11 | 20 | 10 | 27/27 | 50 |

| MGA20-14-ST | 8-14 | 20 | 10 | 27/27 | 50 | |

| MGA20L-11 | 6-11 | 20 | 15 | 27/27 | 50 | |

| MGA20L-14 | 8-14 | 20 | 15 | 27/27 | 50 | |

| M25*1.5 | MGA25-16-ST | 12-16 | 25 | 12 | 33/33 | 50 |

| MGA25-18-ST | 13-18 | 25 | 12 | 33/33 | 50 | |

| MGA25L-16 | 12-16 | 25 | 15 | 33/33 | 50 | |

| MGA25L-18 | 13-18 | 25 | 15 | 33/33 | 50 | |

| M32*1.5 | MGA32-22 | 15-22 | 32 | 12 | 41/42 | 20 |

| MGA32-25 | 18-25 | 32 | 12 | 41/42 | 20 | |

| MGA32L-22 | 15-22 | 32 | 15 | 41/42 | 20 | |

| MGA32L-25 | 18-25 | 32 | 15 | 41/42 | 20 | |

| M40*1.5 | MGA40-26 | 20-26 | 40 | 20 | 50/52 | 10 |

| MGA40-31 | 24-31 | 40 | 20 | 50/52 | 10 | |

| M50*1.5 | MGA50-33 | 25-33 | 50 | 22 | 62/62 | 10 |

| MGA50-41 | 31-41 | 50 | 22 | 62/62 | 10 | |

| M63*1.5 | MGA63-46 | 39-46 | 63 | 25 | 75/75 | 10 |

| MGA63-51 | 44-51 | 63 | 25 | 75/75 | 10 | |

| M75*2.0 | MGA75-56 | 50-56 | 75 | 25 | 92/92 | 1 |

| MGA75-66 | 56-66 | 75 | 25 | 92/92 | 1 | |

| M90*2.0 | MGA90-68 | 58-68 | 90 | 25 | 110/110 | 1 |

| MGA90-77 | 66-77 | 90 | 25 | 110/110 | 1 | |

| PG | ||||||

| Thread | Part No. | Cable Range φ(mm) |

Thread O.D C1(mm) |

Thread Length GL(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PGA7-5.5 | 3-5.5 | 12.5 | 8 | 17/19 | 50 |

| PGA7-8 | 4-8 | 12.5 | 8 | 17/19 | 50 | |

| PG9 | PGA9-5.5 | 3-5.5 | 15.2 | 8.2 | 22/19 | 50 |

| PGA9-8 | 4-8 | 15.2 | 8.2 | 22/19 | 50 | |

| PG11 | PGA11-7 | 4-7 | 18.6 | 10 | 24/22 | 50 |

| PGA11-10 | 6-10 | 18.6 | 10 | 24/22 | 50 | |

| PG13.5 | PGA13.5-9 | 5-9 | 20.4 | 10 | 27/24 | 50 |

| PGA13.5-12.5 | 8-12.5 | 20.4 | 10 | 27/24 | 50 | |

| PG16 | PGA16-11 | 7-11 | 22.5 | 11 | 30/27 | 50 |

| PGA16-14 | 8-14 | 22.5 | 11 | 30/27 | 50 | |

| PG21 | PGA21-16 | 10-16 | 28.3 | 12 | 36/33 | 50 |

| PGA21-18 | 12-18 | 28.3 | 12 | 36/33 | 50 | |

| PG29 | PGA29-22 | 15-22 | 37 | 12 | 46/41 | 20 |

| PGA29-25 | 18-25 | 37 | 12 | 46/41 | 20 | |

| PG36 | PGA36-26 | 20-26 | 47 | 14 | 57/52 | 10 |

| PGA36-31 | 24-31 | 47 | 14 | 57/52 | 10 | |

| PG42 | PGA42-33 | 25-33 | 54 | 15 | 64/62 | 10 |

| PGA42-41 | 31-41 | 54 | 15 | 64/62 | 10 | |

| PG48 | PGA48-46 | 39-46 | 59.3 | 18.2 | 70/75 | 10 |

| G | ||||||

| Thread | Part No. | Cable Range φ(mm) |

Thread O.D C1(mm) |

Thread Length GL(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G(PF)1/4" | GA1/4-5 | 3-5.5 | 13.157 | 8.5 | 19/19 | 50 |

| GA1/4-8 | 4-8 | 13.157 | 8.5 | 19/19 | 50 | |

| G(PF)3/8" | GA3/8-7 | 4-7 | 16.662 | 10 | 22/22 | 50 |

| GA3/8-10 | 6-10 | 16.662 | 10 | 22/22 | 50 | |

| G(PF)1/2" | GA1/2-9 | 5-9 | 20.955 | 10 | 27/24 | 50 |

| GA1/2-12.5 | 6-12.5 | 20.955 | 10 | 27/24 | 50 | |

| G(PF)3/4" | GA3/4-13 | 7-13 | 26.441 | 12 | 36/33 | 50 |

| GA3/4-18 | 13-18 | 26.441 | 12 | 36/33 | 50 | |

| G(PF)1" | GA1-21 | 15-22 | 33.249 | 15 | 46/41 | 20 |

| GA1-25 | 18-25 | 33.249 | 15 | 46/41 | 20 | |

| G(PF)1 1/4" | GA1 1/4-25.5 | 17-25.5 | 41.91 | 15 | 57/22 | 10 |

| GA1 1/4-31 | 24-31 | 41.91 | 15 | 57/22 | 10 | |

| G(PF)1 1/2" | GA1 1/2-33 | 25-33 | 48 | 22 | 60/62 | 10 |

| GA1 1/2-41 | 31-41 | 48 | 22 | 60/62 | 10 | |

| G(PF)2" | GA2-46 | 39-46 | 60 | 25 | 72/65 | 10 |

| GA2-51 | 44-51 | 60 | 25 | 72/65 | 10 | |

1.Before installation, it is necessary to check whether the model of the nylon cable gland matches the specifications of the cable to be installed.

2.Place the insulation sleeve on the cable sheath. Note that the front end should be slightly higher than the height of one shell of the cable sheath.

3.Select a nylon cable gland according to the cable specification and model, and gradually place the gland on the cable sheath.

4.When the nylon cable gland reaches the expected position, tighten it. Use a tapered nut with a cut, first insert a "U-shaped" washer inside the reinforced base, and then fix the tapered nut.

5.The fixed nylon cable gland should be sealed with sealant at the end to ensure both the insulation of the cable and the sealing of the gland.

After the installation of the nylon cable gland, it should be inspected. Verify whether the nylon cable gland is installed correctly and whether there are defects through testing for air tightness and waterproofing.

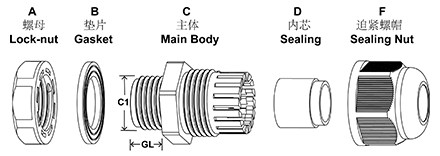

Nylon B-type United Body cable gland is a sealing component widely used in fields such as power, communication, construction, machinery, etc. Its main function is to provide reliable waterproof, dustproof, and mechanical protection for cables passing through it.

The cable gland is made of high-quality nylon PA66 material, which has excellent resistance to environmental aging, chemical corrosion, high temperature, and wear. At the same time, it has good elasticity and plasticity, which can maintain its original shape in different environments, ensuring the safe use of cables.

The cable gland has passed UL fire protection certification, proving that it has undergone rigorous testing and inspection and can safely protect the cable from burning or spreading in case of fire. This is also the main reason why the cable gland is widely used in buildings, public places, and other fire hazards.

In addition, the cable gland has high tensile resistance and strong mechanical properties, which can withstand large tension and pressure. It can also effectively prevent cable bending and twisting, thereby reducing cable damage.

The range of this cable gland is very wide and can be used for different types of cables, including power cables, communication cables, signal cables, control cables, etc. Its design allows for easy clamping of cables and ensures tight connection with other devices.

In summary, the nylon B-type split cable gland is a high-quality, reliable, durable, and efficient cable sealing component. It has multiple excellent characteristics, including fire resistance, waterproofing, strong tensile resistance, etc. It can provide comprehensive protection and support for multiple industries such as power, communication, and construction, and is an indispensable and important component.

| Nylon Cable Gland (B Type United Body) | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range φ(mm) |

Thread O.D C1(mm) |

Thread Length GL(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M8*1 | MGB8-2.5 | 1-2.5 | 8 | 7.5 | 12/13 | 50 |

| MGB8-4.8 | 2-4.8 | 8 | 7.5 | 12/13 | 50 | |

| M10*1.25 | MGB10-3 | 1-3 | 10 | 8 | 15/13 | 50 |

| MGB10-6 | 3-6 | 10 | 8 | 15/13 | 50 | |

| M12*1.5 | MGB12S-3 | 1-3 | 12 | 8.5 | 18/15 | 50 |

| MGB12S-6.5 | 3-6.5 | 12 | 8.5 | 18/15 | 50 | |

| MGB12SL-3 | 1-3 | 12 | 15 | 18/15 | 50 | |

| MGB12SL-6.5 | 3-6.5 | 12 | 15 | 18/15 | 50 | |

| MGB12-5 | 3-5.5 | 12 | 8.5 | 18/19 | 50 | |

| MGB12-8 | 4-8 | 12 | 8.5 | 18/19 | 50 | |

| MBG12L-5 | 3-5.5 | 12 | 15 | 18/19 | 50 | |

| MGB12L-8 | 4-8 | 12 | 15 | 18/19 | 50 | |

| M16*1.5 | MGB16S-5 | 3-5.5 | 16 | 10 | 22/19 | 50 |

| MGB16S-8 | 4-8 | 16 | 10 | 22/19 | 50 | |

| MGB16SL-5 | 3-5.5 | 16 | 15 | 22/19 | 50 | |

| MGB16SL-8 | 4-8 | 16 | 15 | 22/19 | 50 | |

| MGB16-7 | 3-7 | 16 | 10 | 22/22 | 50 | |

| MGB16-10 | 6-10 | 16 | 10 | 22/22 | 50 | |

| MGB16L-7 | 3-7 | 16 | 15 | 22/22 | 50 | |

| MGB16L-10 | 6-10 | 16 | 15 | 22/22 | 50 | |

| M18*1.5 | MGB18-7 | 3-7 | 18 | 10 | 24/22 | 50 |

| MGB18-10 | 6-10 | 18 | 10 | 24/22 | 50 | |

| MGB18L-7 | 3-7 | 18 | 15 | 24/22 | 50 | |

| MGB18L-10 | 6-10 | 18 | 15 | 24/22 | 50 | |

| M20*1.5 | MGB20S-9 | 5-9 | 20 | 10 | 27/24 | 50 |

| MGB20S-12.5 | 6-12.5 | 20 | 10 | 27/24 | 50 | |

| MGB20SL-9 | 5-9 | 20 | 15 | 27/24 | 50 | |

| MGB20SL-12.5 | 6-12.5 | 20 | 15 | 27/24 | 50 | |

| MGB20-11 | 7-11 | 20 | 10 | 27/27 | 50 | |

| MGB20-13.5 | 9-14 | 20 | 10 | 27/27 | 50 | |

| MGB20L-11 | 7-11 | 20 | 15 | 27/27 | 50 | |

| MGB20L-13.5 | 9-14 | 20 | 15 | 27/27 | 50 | |

| M25*1.5 | MGB25S-11 | 5-11 | 25 | 12 | 33/27 | 50 |

| MGB25S-14 | 9-14 | 25 | 12 | 33/27 | 50 | |

| MGB25-13 | 7-13 | 25 | 12 | 33/33 | 50 | |

| MGB25-18 | 13-18 | 25 | 12 | 33/33 | 50 | |

| MGB25L-13 | 7-13 | 25 | 15 | 33/33 | 50 | |

| MGB25L-18 | 13-18 | 25 | 15 | 33/33 | 50 | |

| M32*1.5 | MGB32-17.5 | 13-17.5 | 32 | 12 | 41/42 | 20 |

| MGB32-25 | 18-25 | 32 | 12 | 41/42 | 20 | |

| MGB32L-17.5 | 13-17.5 | 32 | 15 | 41/42 | 20 | |

| MGB32L-25 | 18-25 | 32 | 15 | 41/42 | 20 | |

| M36*1.5 | MGB36-22 | 14-22 | 36 | 12 | 45/42 | 20 |

| MGB36-25 | 18-25 | 36 | 12 | 45/42 | 20 | |

| M40*1.5 | MGB40-25 | 18-25 | 40 | 15 | 50/52 | 10 |

| MGB40-31 | 26-31 | 40 | 15 | 50/52 | 10 | |

| M50*1.5 | MGB50-32 | 25-32 | 50 | 15 | 62/62 | 10 |

| MGB50-41 | 30-41 | 50 | 15 | 62/62 | 10 | |

| M63*1.5 | MGB63-38 | 29-38 | 63 | 18 | 75/65 | 10 |

| MGB63-45 | 35-45 | 63 | 18 | 75/65 | 10 | |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

G.L (mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7 | PGB7S-3 | 1-3 | 12.5 | 8 | 17/15 | 50 |

| PGB7S-6 | 3-6.5 | 12.5 | 8 | 17/15 | 50 | |

| PGB7-5 | 3-5.5 | 12.5 | 8 | 17/19 | 50 | |

| PGB7-8 | 4-8 | 12.5 | 8 | 17/19 | 50 | |

| PG9 | PGB9-5.5 | 3-5.5 | 15.2 | 8 | 22/19 | 50 |

| PGB9-8 | 4-8 | 15.2 | 8 | 22/19 | 50 | |

| PG11 | PGB11-7 | 3-7 | 18.6 | 10 | 24/22 | 50 |

| PGB11-10 | 6-10 | 18.6 | 10 | 24/22 | 50 | |

| PGB11L-7 | 3-7 | 18.6 | 15 | 24/22 | 50 | |

| PGB11L-10 | 6-10 | 18.6 | 15 | 24/22 | 50 | |

| PG13.5 | PGB13.5-9 | 5-9 | 20.4 | 10 | 27/24 | 50 |

| PGB13.5-12.5 | 7-12.5 | 20.4 | 10 | 27/24 | 50 | |

| PG16 | PGB16-11 | 5-11 | 22.5 | 10.8 | 30/27 | 50 |

| PGB16-14 | 8-14 | 22.5 | 10.8 | 30/27 | 50 | |

| PG19 | PGB19-11 | 5-11 | 24 | 11 | 30/27 | 50 |

| PGB19-14 | 8-14 | 24 | 11 | 30/27 | 50 | |

| PG21 | PGB21-13 | 7-13 | 28.3 | 12 | 36/33 | 50 |

| PGB21-18 | 12-18 | 28.3 | 12 | 36/33 | 50 | |

| PG25 | PGB25-20 | 14-20 | 30 | 13 | 36/37 | 50 |

| PG29 | PGB29-17.5 | 13-17.5 | 37 | 12 | 46/41 | 20 |

| PGB29-25 | 17-25 | 37 | 12 | 46/41 | 20 | |

| PG36 | PGB36-25.5 | 17-25.5 | 47 | 15 | 57/52 | 10 |

| PGB36-31 | 24-32 | 47 | 15 | 57/52 | 10 | |

| PG42 | PGB42-32 | 25-32 | 54 | 15 | 64/62 | 10 |

| PGB42-41 | 31-41 | 54 | 15 | 64/62 | 10 | |

| PG48 | PGB48-38 | 29-38 | 59.3 | 18.2 | 70/65 | 10 |

| PGB48-45 | 35-45 | 59.3 | 18.2 | 70/65 | 10 | |

| NPT | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

G.L (mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G(PF)1/4" | GB1/4-5 | 3-5.5 | 13.157 | 8.5 | 19/19 | 50 |

| GB1/4-8 | 4-8 | 13.157 | 8.5 | 19/19 | 50 | |

| G(PF)3/8" | GB3/8-7 | 3-7 | 16.662 | 10 | 22/22 | 50 |

| GB3/8-10 | 5-10 | 16.662 | 10 | 22/22 | 50 | |

| G(PF)1/2" | GB1/2-9 | 5-9 | 20.955 | 10 | 27/24 | 50 |

| GB1/2-12.5 | 6-12.5 | 20.955 | 10 | 27/24 | 50 | |

| G(PF)3/4" | GB3/4-13 | 7-13 | 26.441 | 12 | 36/33 | 50 |

| GB3/4-18 | 13-18 | 26.441 | 12 | 36/33 | 50 | |

| G(PF)1" | GB1-21 | 15-22 | 33.249 | 15 | 46/41 | 20 |

| GB1-25 | 17-25 | 33.249 | 15 | 46/41 | 20 | |

| G(PF)1 1/4" | GB1 1/4-25.5 | 17-25.5 | 41.91 | 15 | 57/52 | 10 |

| GB1 1/4-31 | 24-31 | 41.91 | 15 | 57/52 | 10 | |

| G(PF)1 1/2" | GB1 1/2-32 | 25-32 | 48 | 15 | 60/62 | 10 |

| GB1 1/2-41 | 30-41 | 48 | 15 | 60/62 | 10 | |

| NPT1/4" | NPTB1/4-5.5 | 3-5.5 | 13.157 | 8.5 | 19 | 50 |

| NPTB1/4-8 | 4-8 | 13.157 | 8.5 | 19 | 50 | |

| NPT3/8" | NPTB3/8-7 | 3-7 | 16.662 | 10 | 22 | 50 |

| NPTB3/8-10 | 6-10 | 16.662 | 10 | 22 | 50 | |

| NPT1/2" | NPTB1/2-9 | 5-9 | 20.955 | 10 | 24 | 50 |

| NPTB1/2-13 | 6-12.5 | 20.955 | 10 | 24 | 50 | |

| NPT3/4" | NPTB3/4-13 | 7-13 | 26.441 | 15 | 33 | 50 |

| NPTB3/4-18 | 12-18 | 26.441 | 15 | 33 | 50 | |

| NPT1" | NPTB1-22 | 15-22 | 33.249 | 15 | 41 | 20 |

| NPTB1-25 | 17-25 | 33.249 | 15 | 41 | 20 | |

| NPT1 1/4" | NPT1 1/4-25.5 | 17-25.5 | 41.91 | 15 | 52 | 20 |

| NPT1 1/4-31 | 24-31 | 41.91 | 15 | 52 | 20 | |

1.Before installation, it is necessary to check whether the model of the nylon cable gland matches the specifications of the cable to be installed.

2. Place the insulation sleeve on the cable sheath. Note that the front end should be slightly higher than the height of one shell of the cable sheath.

3. Select a nylon cable gland according to the cable specification and model, and gradually place the gland on the cable sheath.

4.When the nylon cable gland reaches the expected position, tighten it. Use a tapered nut with a cut, first insert a "U-shaped" washer inside the reinforced base, and then fix the tapered nut.

5. The fixed nylon cable gland should be sealed with sealant at the end to ensure both the insulation of the cable and the sealing of the gland.

After the installation of the nylon cable gland, it should be inspected. Verify whether the nylon cable gland is installed correctly and whether there are defects through testing for air tightness and waterproofing.

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

1.Installation time of conventional environment : A type needs 10-15s,B type needs 5-10s

2.Protection degree: IP68-10

3.A : Water resistance:100;Tensile resistance:101. It is suitable for applications with tensile strength of 50 meters water depth.

B : Water resistance:101;Tensile resistance:100. It is uitable for waterproof applications beyond 50 meters water depth.

4.Both A & B type are easy to instal .A type structure is more widely uesd in multiple- hole seal and split seal cable gland in engineering projects.

1.First confirm the hole diameter of the mounting panel hole and chenck if it is a tapping hole.

2.Find the matching thread international standard according to the technical parameter table (Metric,PG,NPT,G) .

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread .

4.Long thread type of cable gland is required by the thickness of mounting panel.

1.Question: Are they UL listed?

Answer: We have finished UL listed and raw material UL (Nylon PA66 made with fire rating UL94V-2) approved .You can choose the one you want according to your requirement .

2.Question: How long is the working life of cable gland?

Answer:More than 10 years under normal environment.

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.

4.Question: Can be accept OEM cable gland & packing?

Answer: Yes,OEM,ODM can be accepted .