Metal Cable Gland

Application field: aerospace field, artificial intelligence robot

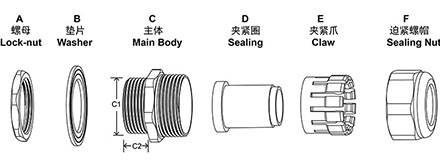

Metal PJA cable gland is a high-quality cable sealing material made of high-quality metal materials, which has the advantages of waterproofing, strong tensile resistance, high temperature resistance, and a wide range of clamping cables. Let's introduce each one one below.

Firstly, the cable gland has reliable waterproof performance, which can effectively prevent water, rain, and other liquids from seeping into the interior of the equipment, thereby ensuring the safety and stability of the equipment.

Secondly, the cable gland has strong tensile resistance, which can effectively withstand tension and is not easily deformed or broken. This characteristic makes it not only suitable for ordinary cables, but also for cables in special environments such as high voltage, high temperature, and high-speed.

At the same time, the cable gland also has high temperature resistance characteristics. It can withstand cables in high-temperature environments and will not deform or melt off due to long-term exposure to high temperatures, thus ensuring the stable operation and safety of the equipment.

In addition, the cable gland can clamp various specifications of cables, with a wide range of applications. Whether your cable is large or small, this sealing sleeve can meet your needs.

Finally, the cable gland is of reliable quality and adopts advanced manufacturing technology to ensure its high quality and reliability. It is not only suitable for various environments and occasions, but also has a long service life, allowing you to feel at ease and at ease.

In summary, the metal PJA cable gland has the advantages of reliable waterproofing, strong tensile resistance, high temperature resistance, and a wide range of clamping cables, making it a high-quality cable sealing material. It can be widely used in various devices and occasions to ensure the stable operation and safety of the equipment.

| PJ-A Type Waterproof Brass Cable Gland | ||||||

| Metric | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| M8*1.25 | M8-3.8 | 2-3.8 | 8 | 5.5 | 13/13 | 50 |

| M10*1.0 | M10-6.5 | 3-6.5 | 10 | 6.5 | 14/14 | 50 |

| M12S*1.25 | M12S-6.5 | 3-6.5 | 12 | 7 | 14/14 | 50 |

| M12*1.5 | M12-8 | 4-8 | 12 | 8 | 17/17 | 50 |

| M16S*1.5 | M16S-8 | 4-8 | 16 | 9 | 18/18 | 50 |

| M16*1.5 | M16-10 | 5-10 | 16 | 9 | 22/22 | 50 |

| M20S*1.5 | M20S-12 | 6-12 | 20 | 9.5 | 24/24 | 50 |

| M20*1.5 | M20-14 | 10-14 | 20 | 9.5 | 25/25 | 50 |

| M25*1.5 | M25-18 | 13-18 | 25 | 12 | 30/30 | 50 |

| M32*1.5(2) | M32-25 | 18-25 | 32 | 12.5 | 40/40 | 50 |

| M40*1.5(2) | M40-30 | 24-30 | 40 | 15 | 50/50 | 50 |

| M50*1.5(2) | M50-41 | 32-41 | 50 | 15 | 59/59 | 50 |

| M63*1.5(2) | M63-44 | 37-44 | 63 | 17 | 67/65 | 50 |

| M63*1.5(2) | M64-51 | 44-51 | 63 | 17 | 73/73 | 50 |

| PG | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| PG7S | PG7S-6.5 | 3-6.5 | 12.5 | 7 | 14/14 | 50 |

| PG7 | PG7-8 | 4-8 | 12.5 | 8 | 17/17 | 50 |

| PG9 | PG9-8 | 4-8 | 15.2 | 8 | 18/18 | 50 |

| PG11 | PG11-10 | 5-10 | 18.6 | 9 | 22/22 | 50 |

| PG13.5 | PG13.5-12 | 6-12 | 20.4 | 9.5 | 24/24 | 50 |

| PG16 | PG16-14 | 10-14 | 22.5 | 9.5 | 25/25 | 50 |

| PG21 | PG21-18 | 13-18 | 28.3 | 12 | 30/30 | 50 |

| PG29 | PG29-25 | 18-25 | 37 | 12.5 | 40/40 | 50 |

| PG36 | PG36-30 | 25-30 | 47 | 15 | 50/50 | 50 |

| PG42 | PG42-41 | 32-41 | 54 | 15 | 59/59 | 50 |

| PG48 | PG48-44 | 37-45 | 59.3 | 17 | 67/65 | 50 |

| G | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| G1/4 | G1/4 | 3-5.3 | 13.1 | 8 | 17/17 | 50 |

| G1/4 | G1/4 | 4.5-7.8 | 13.1 | 8 | 17/17 | 50 |

| G3/8 | G3/8 | 4-7 | 16.6 | 9 | 22/22 | 50 |

| G3/8 | G3/8 | 6-10 | 16.6 | 9 | 22/22 | 50 |

| G1/2 | G1/2 | 7-11 | 20.9 | 9.5 | 26/26 | 50 |

| G1/2 | G1/2 | 9-14 | 20.9 | 9.5 | 26/26 | 50 |

| G3/4 | G3/4 | 12-16 | 26.4 | 12 | 32/32 | 50 |

| G3/4 | G3/4 | 14-18 | 26.4 | 12 | 32/32 | 50 |

| G1 | G1 | 16-22 | 33.2 | 12.5 | 41/41 | 50 |

| G1 | G1 | 18-25 | 33.2 | 12.5 | 41/41 | 50 |

| G1-1/4 | G1-1/4 | 21-25 | 41.9 | 15 | 50/50 | 50 |

| G1-1/4 | G1-1/4 | 24-30 | 41.9 | 15 | 50/50 | 50 |

| G1-1/2 | G1-1/2 | 26-30 | 47.8 | 15 | 60/60 | 50 |

| G1-1/2 | G1-1/2 | 31-41 | 47.8 | 15 | 60/60 | 50 |

| G2 | G2 | 40-46 | 59.6 | 15 | 73/73 | 50 |

| G2 | G2 | 44-51 | 59.6 | 15 | 73/73 | 50 |

| G2-1/2 | G2-1/2 | 50-56 | 75.1 | 15 | 88/85 | 50 |

| G2-1/2 | G2-1/2 | 56-66 | 75.1 | 15 | 88/85 | 50 |

| NPT | ||||||

| Thread | Part No. | Cable Range (mm) |

Thread O.D C1(mm) |

Thread Length C2(mm) |

Spanner Size A/F(mm) |

Std.pkg (pcs/bag) |

| NPT3/8 | NPT3/8 | 4-7 | 17.055 | 13 | 22/22 | 50 |

| NPT3/8 | NPT3/8 | 6-10 | 17.055 | 13 | 22/22 | 50 |

| NPT1/2 | NPT1/2 | 7-11 | 21.2 | 13 | 26/26 | 50 |

| NPT1/2 | NPT1/2 | 9-14 | 21.2 | 13 | 26/26 | 50 |

| NPT3/4 | NPT3/4 | 12-16 | 26.5 | 14 | 32/32 | 50 |

| NPT3/4 | NPT3/4 | 14-18 | 26.5 | 14 | 32/32 | 50 |

| NPT1 | NPT1 | 16-22 | 33.2 | 15 | 41/41 | 50 |

| NPT1 | NPT1 | 18-25 | 33.2 | 15 | 41/41 | 50 |

| NPT1-1/4 | NPT1-1/4 | 21-25 | 41.9 | 15 | 50/50 | 50 |

| NPT1-1/4 | NPT1-1/4 | 24-30 | 41.9 | 15 | 50/50 | 50 |

Compared with the standard one, the hexagon opposite edge of PJA type top cap is widened, which is beneficial to strengthen the wrench strength and water tight .

1.First confirm the hole diameter of panel hole and then advise if there is tapping hole on the mounting panel.

2.Choosing the correct thread international standard.(Metric,PG,NPT,G).

3.If there is no tapping hole on the mounting panel ,you can choose any type of thread .

1.Question: Can customize long thread of metal cable gland ?

Answer: Yes. The shape and screw length of ordinary metal products can be customized after 3D & CAD drawings are provided without new molds (except for special appearance products).

2.Question:Does the signal lamp affect the magnetic field?

Answer:This product can also be used with armor wires to achieve the purpose of EMC anti-magnetic wave.

3.Question: when is the lead time?

Answer: Standard goods can be shipped out within 3-7 business days.Customized model based on the QTY.